After à good print (first try) with new flexible resin & tank, my last print has failled twice -please see images.

When printing, the OBJECT does not sticks to the supports.

I made a print with the same file using clear resin and the 3D file seems OK.

Whan can be the problem?

NOTE: The successfu flexible print breaked in spared pieces when manipulated!

I have the impression that the chemistry of the resin is not OK.

If there is sommeone having resolved these similar problems…

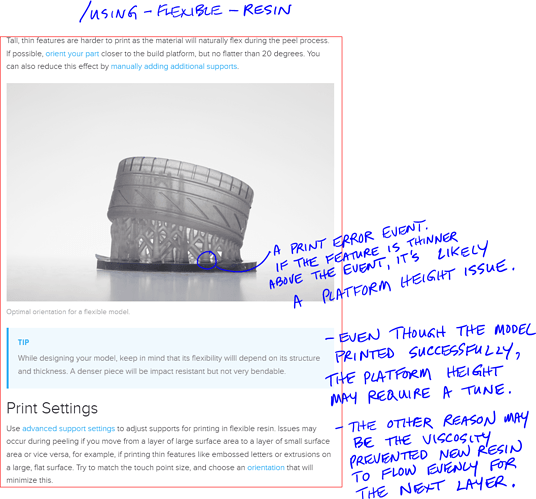

Hi Luis - if you haven’t already seen, we do have some unique recommendations for printing with flexible resin. The resin is substantially different from the standard resins, like clear, so we encourage you to change the print settings rather than use the same file. Most notably, we recommend increasing the touchpoint size. If you have further trouble, would you be able to share the .form file and some images from the side of the part?

@Luis_JARAMILLO It looks like the build platform height might need fine tuning, it’s a little difficult to say for sure from the top view of these pics. As @Stephen mentioned, could you post some pics from the side at roughly a 20 degree angle.

cheers,

Brent

I gave up on this resin. I went thought three bottles, two platforms, two trays, and lots of emails with support. I have one success one almost and all failures.

I tried everything possible, to me it means the flexible resin/form1+ is a match made in hell.

Francesco

Hi @Francesco_Pessolano , in the interest of helping the Form1/Form1+ community, I would greatly appreciate if you could find the time to post a couple photos for me. If possible, close-ups from the side of the support structures and model.

Thanks in advance,

Brent

To be honest, I have been playing with lots of models, settings and so on with suggestions from support. I have not kept any as it was a continuos change.

The problem for me was an is that the resin failed to attach to the base and it detached very early. No matter what. This means that except for the good and almost good prints, all i got was a thin layer of solid resin attached to the tray. wasted resin and wasted trays.

So i wasted lot of money and time for nothing. Support has given me one bottle and one tray back … but with the policy of one coupon per order and unclear of it has to be flexible resin, I am not very happy. Infact, I am considering canceling my form2 order because of it.

I understand your frustration @Francesco_Pessolano , my heavily modified standard build platform began to lose the custom adjust-ability I had built into it. Your explanation "The problem for me was an is that the resin failed to attach to the base and it detached very early." was an event I experienced with my first attempt to print using the “Tough” resin. This event catapulted my plan to design a custom build platform to the top of my project list, well…this and the adjust-ability mod was no longer effective because of general wear on the many contact points within the platform hollow, specifically where the aluminum posts meet the plastic posts within the platform (the eight screws fastening the plastic housing to the aluminum build face).

My custom platform has eliminated these events for me.

cheers,

Brent

My hope is the form2, even if i will limit myself to the tough resin that i have have decided not to even try on the form1+.

Luckily, all other resins works without a glitch and makes my very happy. A buyer without remorse and it si why I am still not pulling the plug on the form2 (even if I am really liking what i see from the NX1 on kickstarter).

But seeing all that resin wasted hurts.

@Francesco_Pessolano are you willing to state and commit in public to your statement that you have no compelling commercial interest in NX1? Your post is really feeling like clickbait to me…

???

I have zero relation to the NX1 and I am even not willing to advice people to buy it. I follow it as I did (and said as many others here) for the Morpheus (which I did not get because irrelevant to my needs) since it is shows something similar to the Carbon3D tech and touches several needs I have on paper only.

I have much more interest in formlabs owning a form1+ (with tons of consumable) that allowed my company to win a design prize and with which I busy for months building some complex models and a form2 on order for which i only doubt when i think and see the word flexible resin!

After a good mixing, tank filled 3/4, model inclination 20° (already donne), augmentation of supports diameter to 1.8mm…

My printing came out OK!!!

Thanks for yours advices.

Regards,

Luis JARAMILLO

JA DESIGN STUDIO

PD: the only regret: bigf resin consumption because of the important number of supports I prefered not to optimize…

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.