Because money….

having now used 20kg of powder from these bags i can attest that they are garbage.

The stupid spout they incorporated into the bags makes a huge mess and requires way too much manipulation of the bag, resulting in a ton of airborne powder. Handling these material trash bags is legitimately the only time i felt that a mask was necessary.

I thought ALM solution was pretty lazy, just a thick back with a reusable zip tie but after handling Formlabs trash, ALM is a way better method. I can control how mach powder is being moved around to the hopper funnel and with minimal mess, albeit more than the formlabs jugs.

I have incorporated recycled kitty litter jigs to hold the excess powder. At least ALM makes sense sending 10kg bags since thier machines hold more than 10kg of fresh powder. Everything about this decision from formlabs just reeks of greed and disdain for customers.

I used my first new “Spout flap” bags…and that thing makes it WAY worse…

They literally added the spout… right off the side of one of the bags many creases/folds… so it does not pour freely as it binds up and blocks powder from being able to flow out without a lot of effort of “fluffing” the bag to agitate it with your hand.

It is still “better”…to stab a hole in the bottom of the bag and NOT the pleated, creased and folded…top of the bag…but still a “trash bag”.

This new flap spout “solution”…solved nothing and honestly makes it worse…

Bring back the Jugs…

The only solution as far as I am concerned is emptying the bag as @LEADNAV suggests. Cut a hole in the bottom and tip it over to empty into the hopper grate. After a few moments I will empty some from the fresh hopper into a cartridge which is then emptied into one of the 3kg jugs I have lying around. No mess, and minimal fuss.

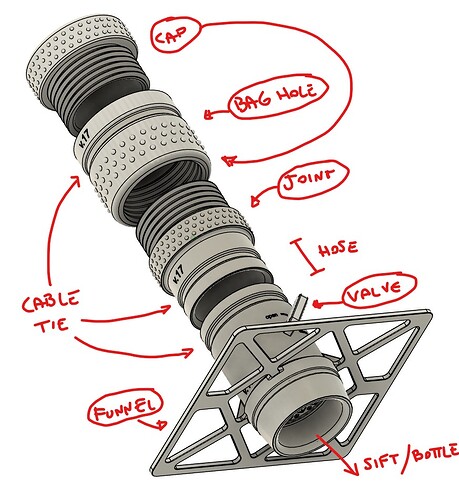

The funnel found on the Formlabs website may be practical but it takes up workspace, so I’ve drawn up a sketch for a personal system for filling the “old” 3kg bottles and/or for directly refilling the sifter.

This is the kind of effort the company should be making to ensure customer satisfaction, not expecting customers to develop solutions for their $10k sift.

Could you show how this is implemented? I’m not picturing it (which is a me problem likely) but Id like to know. Thanks!

Edit- I think I’m getting it now. Cool idea. I wonder if a zip tie will seal the bag to the threaded piece adequately? Are you willing to share the files for this?

They’re currently in print.

I’m currently waiting to receive my first 10kg bag, and this work was done with anticipation in mind.

If it works, I’ll be happy to share the file.

![]()

Good morning everyone, stepping in to say hello. I will be managing our powder packaging options moving forward. I’ll try to be as transparent as possible and update here when I have info that can be shared publicly.

We know that the 10kg bags have been frustrating to use and we are actively working to make it better, either through a device that makes the bag easier to use (like Skylink’s nozzle above) or different packaging options. We distribute powder all over the world, so any changes we make will take some time.

I don’t have more to update at the moment, but feel free to follow up if you have any questions that haven’t been discussed yet and definitely keep the ideas flowing. We love the inventiveness of our community. (My responses times will vary dramatically on here, so please be patient.)

Great.

Waiting for good news.

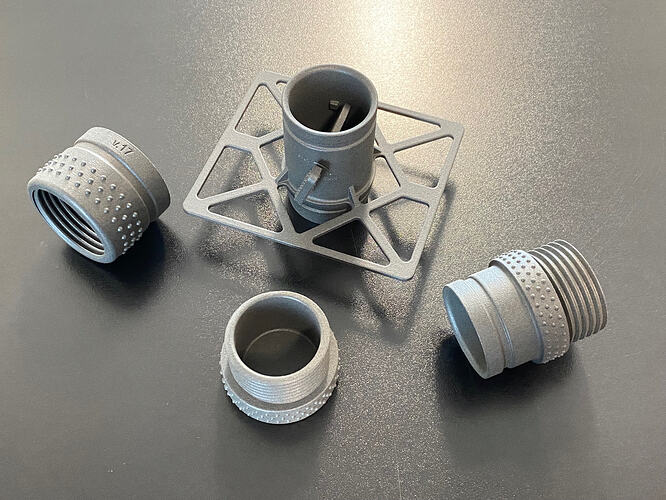

In the meantime.. this is my attempt…

(not only recycle but also reuse!)

Some tollerances to adjust but i think it should works!

Formlabs better pay you for these models if they want them.

Nice!

I increased some thicknesses but I haven’t had a chance to test them because I have other urgent matters at the moment.

Anyway… if you want to try playing with it, these are the files.

Powder_Refill_v19.zip (12.5 MB)

Wouldn’t it be better to add a screw cap to the bag? So it will be easier to aim while pouring or even connect it directly to the opening. Closing an opened bag will be done with a twist of the cap.

This would still help with the recyclability/landfill issue and storage when empty but most likely improve the work of daily Fuse1 users.

@Mr_Solissa this is one of the options being considered. Good thinking.

That would be ideal, expect price increase with 25%. Thats just reality sadly.

Formlabs should just hire you to “put their material back into the original jugs”… ![]() or someone should just start a business of selling Formlabs powder back into a jug…

or someone should just start a business of selling Formlabs powder back into a jug…

This SLS system was already very “niche” in its use cases especially in a production business model.

Restricted to only small parts where you can fit 75-100 units per chamber. That way any flaw in a part only affects one or a row of smaller parts.

I get folks all the time that want us to print larger parts where only 6-12 units would fit per chamber but this is not possible “as is” in material and machine upkeep costs alone.

Unless you have the ability to charge those “aerospace” prices or simply offering prototyping services.

With the original jugs at least…there was nearly a “zero” percent chance of outside contaminants making its way into the fresh powder hopper…with only a slight and rare case of a hair or dust making its way into the cartridge if the top is not vacuumed before filling and/or from the Fuse hopper as you dump it in…

With the jugs, once you “pop the top” and flip it over the fresh hopper… there was NO OUTSIDE chance of contamination in a completely closed system… it was perfect.

If Formlabs does not add this in a bag with some sort of hard screw cap “docking spout” on the bag…there is ZERO chance that they will fix or improve the damage they have done to this system.

With these darn bags we have up’ed our failure rate ALOT more frequently… so it even makes doing larger parts nearly impossible due to the percentage of failure across a single taller part in a chamber…

The right thing to do would be to go back to the jug…as the rest of your material portfolio is still in…and maybe fire the person who thought this to be a good idea…

This change alone has pushed this system over the edge and not worth the gamble on a lot of larger parts and/or outside jobs with its increased failure rate…and limits it to only our in-house, direct to consumer higher end $$ market and even then…it now has us looking to go back to CNC and aluminum on the bulk of our larger parts and assemblies with only SLS printing our smaller components.

Yes, I also think a “closed” system that prevents possible contamination is essential.