You have to empty some in the cartridge to get the whole bag in without making a mess. Did your filters catch anything? I haven’t had the issue of contamination in the bags knock on wood.

This bag was clean.. previous bag had bag curly Q chunks that locked up my powder flipper.

Have you tried popping air bubbles created in hopper? I use a clean rod or clean nitrile gloves and use fingers.

I agree that a hair or microscopic small pollution is easy get into the powder. I had to cut the big bag into 2 parts because a small amount of powder has left in the bag. than I saw, to my surprise, that there were some very tiny parts of foil in my powder. They were so tiny that even the finest sift could not seperate them. I was ver sad about tis, becouse you never know if ther emore small parts of the foil are in the powder.

At this point I’ve held off ordering my next bulk Nylon 12 order. I just ordered an individual bag of nylon 12 yesterday as I ran through the last of my bulk order this week. I’m hesitant to order in bulk until Formlabs at least releases what they’ve decided to do as I was last told about a month ago that they were having serious round table discussions about this bag situation…but obviously they have not responded yet to any of this.

At this point we’ve seriously thought about the open material license to switch to another jugged or canned Nylon 12 powder just to get back to the ease of using the system.

I see that they have the Fuse license now hiked up to over “$11k” so I’d assume they would still be supportive through warranty for that much as its dang near half the cost of a new Fuse itself added to the high yearly service cost…in just two years… you’d have nearly paid for a another Fuse all together!

i have an open license and i am severely disappointed in the messages i have gotten from formlabs about it. Its worth noting that the license is not a yearly fee. its a one time charge but PER MACHINE.

Do you due dilligence for the functions in the fuse and sift that are disabled when using OMM. even the print monitor isnt compatible and last i heard, formlabs solution to the print monitor killing prints, because of a lack of camera exposure configuration, was to disable the print monitor completely.

i don’t know if they have implemented this yet, this company moves at a snail pace compared to how fast my team of 4 can develop software for million dollar pieces of equipment.

Honestly, if i had to choose what machine to get again, i would just skip formlabs completely. It still feels like a hobby machine pretending to be an enterprise grade product. It isnt even compatible with common enterprise network security and so rediculously locked down that there is an argument that you dont even own the machine you paid for.

Hi everyone,

Thank you for continuing the discussion and for the ongoing suggestions! We hear and appreciate your feedback.

We’re continuing to investigate our options; however, implementing significant changes takes time and planning. Many of you have shared partial solutions and accessories that can help improve the experience in the meantime, and we appreciate the community being proactive as we explore permanent solutions. We’ll be sure to provide an update as soon as we have more to share.

Best regards,

Sophia

An amazing Customer service response, like the ones we can give when something goes wrong and it’s on our side.

It will be much better to be transparent about it, and sell the material at a lower price and getting the jugs back because as some have pointed out the rest of materials come in jugs still….

This might justify selling material at higher than $35 per kilo, but keeping local distribution availabilty and the jugs the whole ecosystem was designed for. Probaly no one would be complaining if the material was still sold the way it was.

OR you can go corporate as Stratasys and 3dsystems, and create the SIFT 2 of Sift + allowing the clean use of the bags and keep selling chinese material at premium prices.

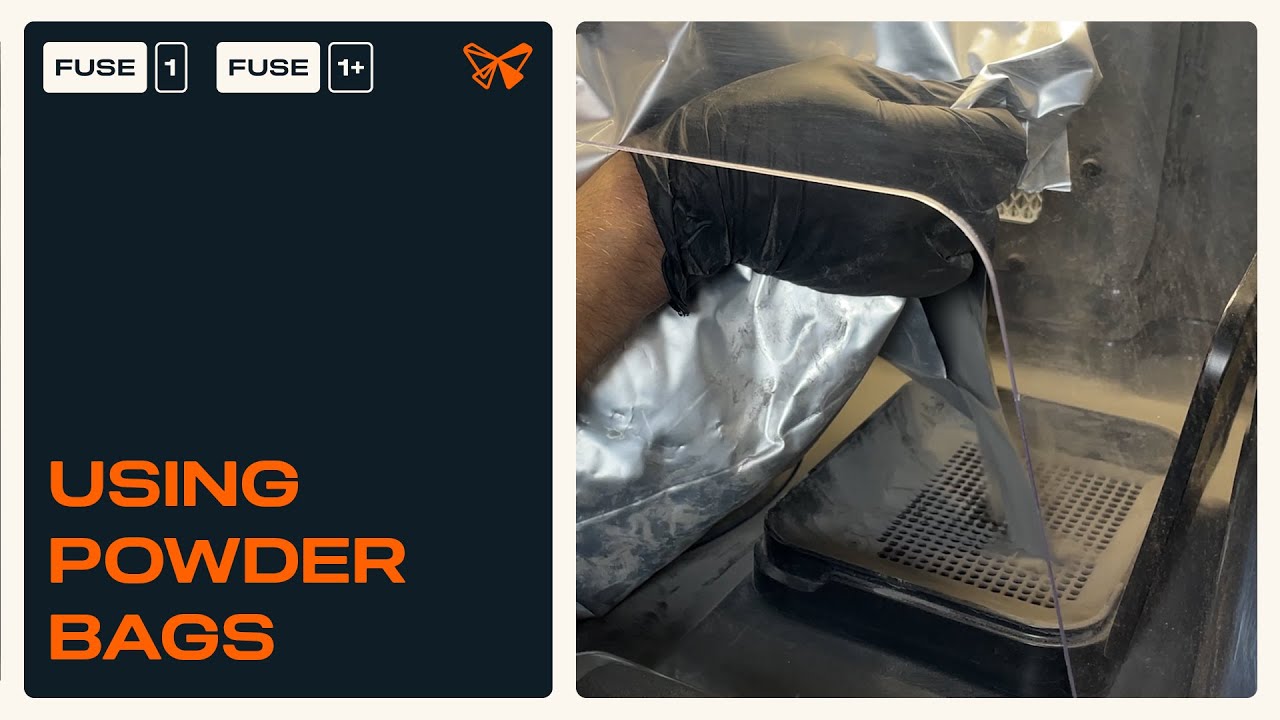

Hi all! Just wanted to pass along our video demonstration for using the SLS powder bags with your Fuse 1 generation setups. I hope that it can clarify some different techniques that you can use to most easily refill your Fuse Sifts.

This video covers everything from adding powder credits, installing the funnel, two different pouring techniques, and a note on storage.

I just watched a video from formlabs on how to properly use the new bags and I have to say that it really blows my mind. Formlabs has always been a company focused on user convenience and I appreciate them for that despite the higher price of their products. I would be extremely interested to see how many dollars they save if they invented bags to save money instead of the original perfect system. Is it really worth it for them? To damage their reputation like this? It’s unbelievable. I use bags in an easier way but I still hate them. They are inconvenient and handling them is very bad compared to the previous method. In addition, the jugs found a use even after they were used and other companies in the neighborhood also used them, so it cannot be said that plastic waste would increase. On the contrary.

Yea I agree…I watched the video last week and I have just kept to myself as I am still trying to wrap my head around its overall production value and waiting on a few other responses haha

So…there is a new “spout flap” added to the trash bags is what I’m gathering in which I assume we will see whenever their current stock pile of old Nylon 12 trash bags deplete eventually?

That’s at least a step in the right direction and helps with the problem of us having to decide where to best make a cut somewhere on these “origami” inspired bags.

The video itself could have been 1 minute long with that small bit of information as we were not really requesting all the other basics on how to use the credit card system, etc.

However, as I sit here watching it again, her still needing to overly manipulate the bag over the Sift with her hands and arms all over the place…I am still just visualizing all the static cling “lint, dust and micro hairs” entering that fresh hopper as still a major problem this has all introduced. Not to mention the extra dust in the air and spill over outside that grate.

Then, the problem of rolling that bag back up, while introducing even more static contaminates while storing till you have to overly manipulate it some more a second time over the fresh hopper…that was never demonstrated.

Our failure rate due to these contaminants has greatly increased since no longer using the originally designed fully enclosed “pop top” jugs with a perfect docking spout with ZERO chance of any of those contaminants making it into the fresh hopper.

It seems like the original jugs were designed by the brilliant engineers who brain stormed this whole ecosystem, perfectly in my opinion, as far as hardware goes… unfortunately it looks like a COO and profit team was a key factor in this new trash bag decision.

Such a huge downgrade in the entire ecosystem of this setup…it’s a dang shame.

In other News: I just heard Apple is looking to finally pass on the torch from Tim Cook (former money guy turned COO) to possibly John Ternus (Long time Engineer of Apple)…to bring Apple back to its roots of actually designing great products! ![]()

I’ve also been keeping quiet because FL did deliver the video we requested… it’s just not exactly what we were hoping for. The jug system was perfect from a user perspective, and it is a shame we no longer have means to use it (other than filling jugs from the bags which seems inefficient).

I’ve had the “spout flap” on the past 10-15 bags of powder received. I agree it’s a step in the right direction, but I find that it’s actually more difficult to use than simply cutting off a corner. You have to constantly jostle and manipulate the bag to get the powder to flow out of the spout. I think it could be improved by rotating the spout 90° and moving it to the top edge of the bag.

I would not suggest tearing open the bag like they demonstrate. I’m pretty sure that’s how users have ended up with debris directly from the bag. Cutting off a corner past the pleated edge is easy, clean, and works for me.

For me, the best way to deal with the bags remains cutting a circular hole and draining the powder directly through the grate. If you rest the bag directly over the grate (covering it) very little powder escapes. The catch is you have to fill a cartridge to drain excess fresh powder, which then has to be transferred into another container for storage. I’ve done this a handful of times and its worked very well. I’ve not seen any bag fragments in the powder/print either knock on wood!

The video was just like the bags, trash. (sorry but thats my opinion)

Im still dreading the day the bags show up here with Nylon 12GF in them.

SMute

I have been trying something similar in with the two cartridges I have…the key being to dump the entire bag in versus storing the left overs.

With two cartridges, I basically run the fresh hoper down way lower than you should.. because the low powder warning is not perfect this involves me opening the hatch and staring down there with a flashlight (while trying not to drop a dust particle or micro hair down there) to make sure I down’t totally run out of fresh powder on a cartridge fill. I try to get it as low as possible. Then I fill it to the top with a “trash bag” of powder and pinch it off before it overflows. Then I do two cartridge fills (I run Nylon 12 at 40% refresh). Then I continue to fill the rest of the bag in.

Still a pain in the A… and involves a lot of extra forethought in running the printer and fresh hopper all the way down…bone dry.

Still hard to prevent contamination and still frustrating when the original system was so perfect and thoughtless with the jugs.

Especially since they could have designed something for users to print (cause they are way too cheap to include a mechanism in the purchase) that breaches the bag, acts as a control spout and seals the bag if it isn’t consumed.

But, they would rather wait for their beta testers (us) to find a better solution.

I’d rather see their powder credit system challenged in court. It’s. Shame HP settled their third party ink class action lawsuits. That precedent would tear formlabs business model to pieces.

They didn’t realize customers asking for bag video demonstrations was bait to put their bad business practices on video. ![]()

Tone deaf in so many ways.

I haven’t been affected by the “trash bags” yet myself, since I’m printing with Nylon 12 GF. However, I’m seriously concerned that this miserable system will soon be introduced for that material as well – so I’ve been following the current issues closely.

I’ve already given it some thought: like LEADNAV mentioned, I would try to run the fresh powder hopper down as close to empty as possible. When it’s time to refill for the next print, I’d open a new bag and place the opening directly over the funnel, letting the powder flow in on its own using gravity. In the meantime, I’d fill the cartridge and printer as usual.

I think this method could allow you to use up an entire bag in one go, without having to store any leftovers. And since the bag sits directly on the funnel, there shouldn’t be any risk of contamination from dust or particles.

Happy to be corrected if I’m missing something!

I haven’t been affected either since I don’t use formlabs powder at all but it still irritates me.

Kinda like Formlabs deleted Direct Messages to me from other members. Apparently they forgot I have email notifications and they can’t retroactively delete those.

Knowing that we are all pissed and tired about this change, which had an important impact on the Fuse ecosystem, why doesn’’t Formlabs just acknowledge the situation and take the right actions?

Apple rolled back aluminium for the new iPhones after promoting titanium because they admitted it was not the best technical decision. I think that Formlabs could do the same with the plastic jugs and they will only be stronger!