Please

After wrestling with getting a decent casting from the FL resin, I’ve been forced to evaluate every aspect of sprueing , investing and casting, as well as printing and printing resin. I think the best place to start is go back to what I know works for wax and adjust from there, I have a bottle of Bluecast but before I use it I am going to make sure the prints I am printing with it actually print, its seems best to start from the beginning which is to make sure also that models designed for milling will print, closed surfaces , parts actually intersecting and making full contact, there is a lot you can slide by with in a milling operation, and frankly I’m going to choose the easier way most every time, I’ll keep you guys posted, Ill be casting by Thursday if not before

i got the spray now and realised that theres only one kind of wd40 ptfe spray :). already using bluecast, bought casting equipments, however, my cast stil seems not perfect ( i think no porosity but rough surface, straight from the cast), though the details were great. im using optima prestige and kerr cast 2000 and 8 hours burn out, getting same results. any suggestions?

Hi, looks like your final part of ramp has too low temperature. Please check furnace real temperature with IR thermometer.

Wax channel also looks affected by this.

If you cannot check temperature just shift up whole cycle 100 150 celsius to fix.

I

Blue Cat, when you say the wax channel, do you mean the sprue?

Thank you for sharing kristian1990

Yes, main sprue.

my max temperature is already 820 celcius for 4 hours. so i will make it 920 celcius? im thinking of the investment degrading due to high temp?

@katkramer, I’m definitely interested in hearing about your experiments with sprues.

Sorry for the delay on my reply…

My first guess is that your burnout temperature is too high… I know the BlueCast folks talk about using a higher burnout temperature, but I’ve gone back to a lower one based on the recommendation from R&R. My highest burnout temperature is 1375°F ( 746°C ), and I’m holding for about 3-1/2 hours. According to R&R, they say that at higher temperatures the investment can break down but also it results in problems with burnout because there is not enough oxygen at the higher temperatures…their words, not mine. When I lowered the temperature to the 1375°F/746°C, I suddenly got better casting results.

Also, my final temperature before casting is 975°F (523°C), but I’m using a vacuum-assist casting setup. I understand that with vacuum casting you’re supposed to have a slightly higher final temperature because the temperature can drop about 100°F per minute (38°C). I’m also using perforated flasks, with the largest being about 4”x4” (10cmx10cm), but mostly about 3-1/2”x4” (7.5cmx10cm).

The second thing I would question would be the type of investment. I’ve tried SatinCast by Kerr, which worked fine, but switched to PlastiCast (without Bandust) by R&R. Formlabs recommends using PlastiCast with Bandust, but I can’t get this type from my usual suppliers (Rio Grande in the US). I’m not familiar with the Kerr 2000, but I know that certain investments are recommended for casting with resin…traditional investments may not work as well…the new ones are formluated for these newer materials. Upon looking up Kerr 2000, it says it’s an “economical alternative to SatinCast…and has a slightly less smooth surface.” That might be part of the problem.

And I’ve had various posts on the forum…and on one thread I talked about putting more sprues with the thought that I’d have better airflow. I’ve since scaled that back. The first thing I’d try on your ring is to use a smaller sprue. I can’t tell what size the sprue is, but the largest I’m using these days is a 3mm. However, on some smaller pieces I’m using a 2mm sprue and it works just fine. My guess is that what you’re seeing is shrinkage porosity. I’ve started designing my rings so they are a consistent thickness, hollowing out the back side to eliminate weight, but also to make a consistent thickness which is casting very well.

I’m self-taught in casting, so everything I’ve learned is trial-and-error, so I recently took a wax carving and casting class with Kate Wolf…she makes wax carving tools that are pretty awesome. The highlight was a discussion about sprueing, and she even talked about “risers” to help control shrinkage with the metal (she seems to think they’re pretty unecessary if you sprue correctly).

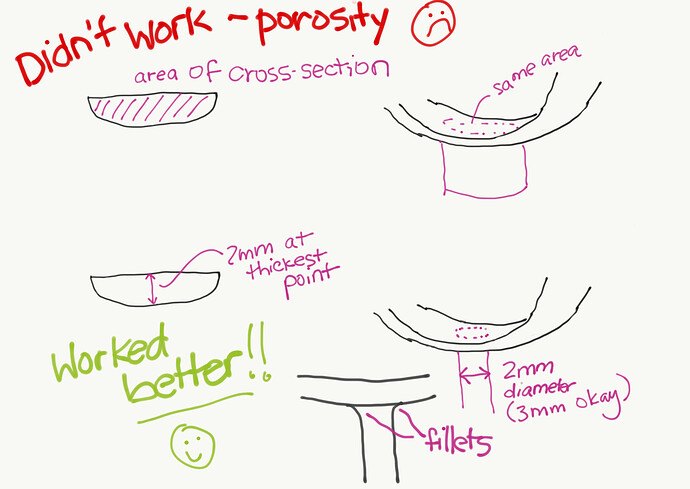

Anyway, I brought in some of the pieces that looked pretty bad and we talked about the sprues. Her recommendation was that 1) my sprues were too big, and 2) that I had too many of them and the extras were unecessary for the size and thickness of the ring I was casting. When I removed those sprues, and went back to a smaller main sprue, it cast perfectly. I was looking at the overall cross-section of the shank and thinking that I needed to match the area of the cross-section of the sprue to the cross-section of the ring…her advice was that the thickness of the sprue was better matched to the thickness of the band, or the thickest part of the ring, of course attaching the sprue to that thickest part. Anyway, the first thing I would try is a smaller sprue…if that doesn’t work, I’d try the PlastiCast investment.

Forgive the crudeness of the drawing…it’s just a quickie. It’s not gospel, only a depiction of my recent experiments and what is working for smaller rings and jewelry. Anyway, let me know how it turns out!

UPDATE: @rji5668’s wonderful signet ring below uses a heavier main sprue and two feeder sprues to the top…so my advice may only be relevant for the thinner ring above or smaller items. Read on!

Kat

I also found the r and r sweet spot to be 1375 fahrenheit. I hold for 4 hours. Has been working great for me. Kerr satin cast is no longer available. Kerr went out of business last month. Satincast works great for me for milled wax but not at all for resins. I have been mixing flasks with milled and grown products in the Rand R (no bandust) and have been getting good resuits

I cast some very large rings (20-30 dwt each) and put a very large sprue at the base and run feeders 3mm each to the top sides. Help me gett better detail on the tops. Lots of emblem rings with fine detail… will post some pics.

Wow! That looks great!

KERR WENT OUT OF BUSINESS?? Whoa! Hopefully I’ll still be able to get those crucibles for my ElectroMelt. Maybe I can finally get that wax pen at a discount somewhere! (I have a little Foredom that I love…a great size for travel…you know, doesn’t everyone bring their wax pen on the plane with them when they travel?)

On your top, do you know what the height of the raised design is? It looks like a nice, deep print. Also, you mention “very large sprue…” Can you describe about how large? Round or oval? In my experience, my smaller sprues are working, but I only make smaller items. I know someone else working on rings like this who might benefit from your experience (@Paul…I invited you both to a private group message).

Are you using Castable V2 or other?

Many thanks!

Anything you need Kerr related i would order ASAP. My supplier said that some of the items will be available from the original mfg who made for them but i would not count on that. I use 2 different type of sprues. When i put the base on manually, i use a 6.5mm wire for the base. Sometimes we have the cad program put on the base. Will give me a base proportionate to the size of the shank.

Using the bluecast resin. hops this helps

I’ve started adding the sprues in ZBrush, which is so much easier. Are you using Matrix or Rhino?

Thanks so much for the info!

Ordering crucibles now!

using the latest version of matrix

art rosenfeld

rosenfeld jewelry

lyndhurst, ohio

Kat

here is one I cast today. this is a milled ring but I sprue the resin the same way.

art

Same program and 5 revo mills and 4 solidscapes and formlabs2 incase you need anything

philadelphia pa

Art, is this sterling silver? Do you mind me asking what metal temperature? Thank you so much!

And thank you, @George_Earussi!

I’m in Austin, Texas. ZBrush, Form2…

Kat

I use tru silver casting grain from hoover and strong. I cast at 1825F metal temp and 900F flask temp. Using a memco electrovac with a nitrogen/ hydrogen gas mix.

George, any chance you cast stainless steel? have a customer for some motorcycle logo rings but wants stainless

art

Ah…I had to look up TruSilver. I’m using something similar from Rio…anti-oxidation casting grain. I’ve actually had problems trying to get it to take a nice patina. Thanks for the info on the temperatures…I’m casting at around 1865°F (1018°C), which is at the top end of what they recommend…I was having a problem with it not being fluid enough. Using a KayaCast vacuum system. Sounds like you have a really nice setup!