I experienced a calamitous drop in reliability immediately after I installed PreForm 2.11.3, and it’s been steadily deteriorating ever since. I used to achieve over 90% success even with difficult material, but it’s getting so severe that I’ve had 0 successes in my last 25 jobs, Perhaps there’s more than one issue, or there’s a fault in the machine itself?

Here’s a quick tally of my success rates before and after updating PreForm to 2.11.3, organized by material:

Clear:

Before PreForm 2.11.3: 50 of 50 jobs (100% success)

After PreForm 2.11.3: 1 of 13 jobs ( 8% success)

Durable:

Before PreForm 2.11.3: 12 of 12 jobs (100% success)

After PreForm 2.11.3: 0 of 13 jobs ( 0% success)

White:

Before PreForm 2.11.3: 64 of 70 jobs ( 91% success)

After PreForm 2.11.3: 0 of 9 jobs ( 0% success)

Tough v3:

Before PreForm 2.11.3: 32 of 34 jobs ( 94% success)

After PreForm 2.11.3: 13 of 30 jobs ( 43% success)

Tough v4:

Before PreForm 2.11.3: not tested

After PreForm 2.11.3: 0 of 14 jobs ( 0% success)

Before 2.11.3 my success rate with Durable and Clear resins had been 100%, no failures until I updated. After updating, I’ve only had 1 successful job between both of those materials. Only Tough v3 exhibited enough successes to be useful but I ran out, and I haven’t yet succeeded building anything with Tough v4.

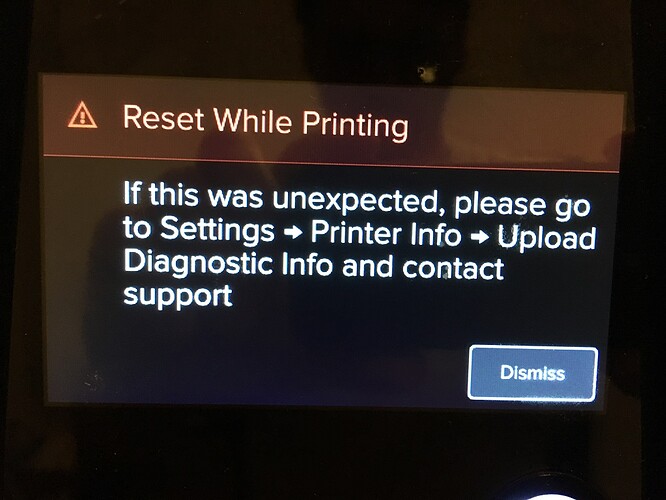

I recently updated PreForm and updated the firmware, and the situation has worsened: instead of attempting a job and failing, the machine won’t even start building.

- Tough v4 starts building, but quits with Error 41

- Clear jobs raise a squealing sound, then the machine goes dead (black screen, bezel light goes out)

- White starts building, but quits with Error 41

Although my build failures certainly started when I updated to PreForm 2.11.3, maybe the timing was coincidental. No one else has reported an impact as bad as that.

Do these “error 41” and abrupt blackouts suggest there’s a fault in the Form-2 itself?