Downloaded the new 2.14, Form 2 has latest firmware.

Models built in ZBrush and exported as STL. All polys combined are under 1 million.

Import into PreForm as typical, auto repair promted but went quick. Orientation was difficult but eliminated all minima errors (<15) and cupping (auto-orient would place models with cupping warnings, manual reorientation and adding supports manually got rid of the errors.

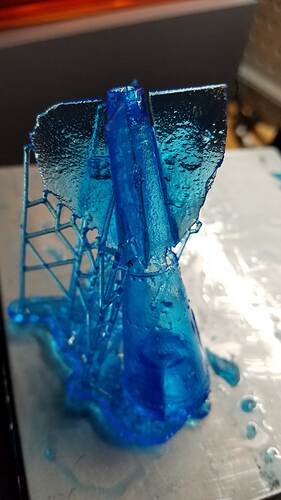

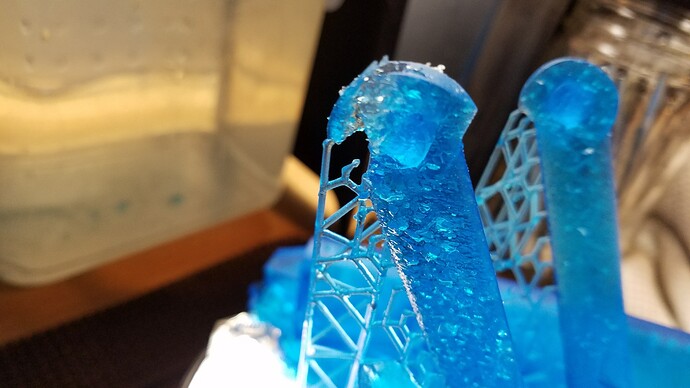

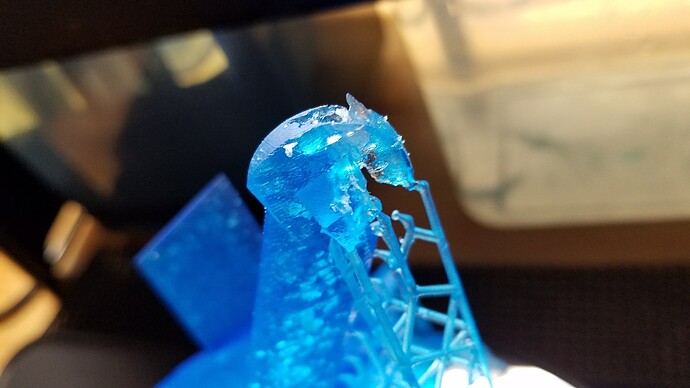

Portions of the prints look fine but others have a “furry” or “flecking” appearance.

Others are missing chunks.

Removal of parts from plate was VERY difficult…rafts were sticking like glue. Drain holes are on both ends of the hollowed item. The rest are solid. I did not screen the resin after this print, I did visually inspect the tank/resin and there were no chunks or other particles in it.

I had a previous issue with air bubbles between inner/outer walls and it turned out to be dirty glass and modeling the walls too thin - not an issue with this one. The chunks missing on this latest print is a scary first.

Tank was used previously though 80% of a cartridge of TR04. Swapped out the previous bottle for a new bottle of TR04 since I needed more resin volume for this bigger print.

Printing another model with the same tank, resin, plate to see if it prints as good as the print before this fail. Want to see if its the model (I am not perfect) or the printer.

Glass was cleaned IAW FormLabs guidance. Resin is new (e.g. not opened) but bought a couple months ago. Bottom of tanks look fine, nothing visually perceptibly wrong.

The build plate (z-axis movement?) makes a random binding sound (sorta like stomping on brakes in a car) when It is lowering and raising between layers but it is random, not when the laser is printing to the plate. It has not affected previous prints and has not gotten louder or more often.

If I had one request it would be an option to disable auto detection of the minima and cupping errors. Importing multiple pieces means lots of CPU being ate up to tell me I have unsupported areas when I haven’t even added supports yet. I am trying to auto orient the models and I am getting error warnings. Also, auto-orient positions models with cupping and warnings, manually flipping the end up IAW FormLabs support page and the cupping warning goes away.

Any help is GREATLY appreciated.

Can room temp fluctuations affect prints this way?

Can room temp fluctuations affect prints this way?