Hi all,

I’ve an issue with medium size components printed with my form3 and Flezible 80A resin.

Here some photo of the problem:

I’ve used the One clic option for prepare the item.

Here you can see the stl file:

Item1.stl (141.8 KB)

I’ve tried to print this object for two times (with different orientation and different supporto strategy), but with the same results.

Some have any ideas?

Thanks,

A.

1 Like

Move the part to a different area on the build platform try it around 30 degree angle with either adding support manually or letting preform do it automatically. Try running it again also double check that the tank isnt damaged or expired.

1 Like

Hi Matt, thanks for the reply and sorry for delay.

I’ve tried with an angle of 30°, but the result is the same.

Otherwise, I’ve tried to print another item with the same issue.

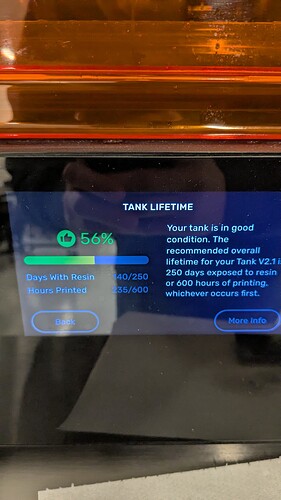

Here other images. The tank is in the middle of his life with a reasonable amount of hours.

1 Like

Whats the bottom of the tray look like it may be failing Ive run into this issue occasional with Flexible 80A currently we are running a job and it just happened on this job the issue is we run build after build after build when ever it is ordered and if we dont rotate it after about 3 builds it will start sticking to the bottom almost like when a image would get burned into a old TV so i try to remember to rotate the build 90 degrees each time with better success this instance (see Below) I forgot and it stuck.

The build you show there you probably could go vertical with proper supports the wide end at the top but I would check your tray first you may have resin stuck to the bottom or it maybe failing and starting to go through the first layer.

1 Like

I can try, but i deep clean the buildplate after every print with IPA and paper. It’s correct?

1 Like

Sorry are you talking about the resin tank or build platform that you clean after every use?

I’m talking about the buil platform.

I only cleaned the resin tank once several prints ago, due to a print failure in which debris was left everywhere.

Hi @AndreaLillia! I’m sorry to hear that you’re running into these issues! While there are many variables that could be affecting your print success, I’d like to highlight a couple things you can try.

The first is ensuring that your resin tank is fully clear of any cured resin debris. After any print failure, if not fully cleared, there is a chance that lingering debris can cause subsequent print failures.

You mentioned that you cleaned the tank the other day – great! – it might still be worth while to review our video on cleaning debris in the resin tank for both the Form 4 and Form 4L.

While this video is Form 4 generation-centric, it covers all of the best practices that are applicable across all of our SLA printers. I hope it helps!

The second is to ensure that your optical window is not contaminated. Over time, the window can accumulate dust and dripped resin that can block the laser in the Form 3 and lead to print failures.

We have another video with guidance to do so here, I hope you find it helpful!

2 Likes

the build platform shouldn’t cause any of these issues I was saying check the bottom of the resin Tank and see if its failing.

1 Like