As a startup we decided to create a device that does some amazing things and during our earlier development sessions I convinced the team that we should get a Form 2 rather than depend on outsourcing our prototyping. We purchased the Form 2 and Meccatronicore BB Cure and plenty of supplies such as spare trays, resins, etc. which ended in a whooping $10,000 which is a healthy chunk of are startup capitol but would be well worth it if the machine worked.

After a couple of months I can say I feel more like a Form 2 technician then a startup guru on my way to success. My team is so disappointed in my choice as we are not able to print prototypes and the entire team is held up but still must be paid. We are at risk of losing our entire project because of this and currently Formlabs cannot figure out what the issue is after over a week of going back and forth with support at about 1-2 messages a day. Even worst is we decided to have our new unboxed Form 2 air lifted to Costa Rica before beginning because many of our team members reside there. This also means if Formlabs can’t call tag the unit from Costa Rica we will have to pay for someone to take it back to the U.S. and then pay the customs fees again to get it back here again, another $1000 not to mention the 2 new tanks and 2 new bottles of resin wasted on trying to troubleshoot what is causing this issue. What an expensive mess I’m really deflated by this incident as all these people counted on me to make a great decision and I feel I have failed them by choosing the Form 2.

Can someone please look at these images and see if they can figure out what the issue is? Huge thanks to whoever can take some time on this. I’m just hoping this can get resolved and we can finish our project and this issue is something minor.

The first sign of the issue was many lumps and bumps in the print. I knew this could not be right if this printer could also be used for jewelry casting because no lines and imperfections should exist. I reached out to Formlabs before this print and had them assist me with orientating and supporting the print properly and it gets a green checkmark in the software saying it is supported properly so the issue was not with the supports.

At this point I resolved with the help of support that we may have some bad resin or maybe the resin was not shaken properly so I strained the resin with a 190 micron filter and replaced the tank and this is what I got.

This type of failure happened again and again as I made adjustments until I could adjust no more. Formlabs asked me to perform an optical print which I still have not heard back on what was diagnosed from that as it has been Easter weekend. Here is what that came out looking like.

At this point I felt incline to try to figure this out with proper troubleshooting since as I mentioned the team has been placing a lot of pressure on me and I was not allowed to take holiday. So thinking this may be a model issue I decided to print a model that I had success with when we first used the printer, a unicorn. Needless to say it failed also having small hols, and lumpiness even though it was printed on the highest resolution for the resin.

So at this point I was thinking its a white resin issue and maybe I have an entire bad batch I decided to switch resins to clear resin and try a normal print. I was elated by the results as I though I had isolated the issue to the resin itself because the print came out well.

Since this worked I decided to take a brand new tank and a brand new bottle of white resin and give it a whirl with the same part. Success!

Okay so it seemed I had narrowed down the issue to either faulty resin in my first batch or maybe a bad tank in order to rule out everything. I then gave it another shot with new well shaken white resin and a brand new tank. FAILURE of maximum proportions.

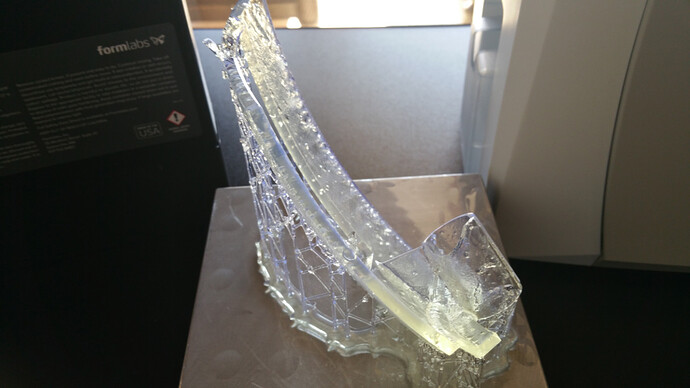

The last thing I was left with was to try the clear resin on this part. I had to stop the printer as I saw it would eventually fail. As you can see the ragging on the clear resin, the bumps on the part and the scaffolding supports, the globs forming in between areas etc.

At this point we are stumped, I do not know what to try further and we are dead in the water.

Hopefully they can call tag it via UPS or FedEx and get one back to us under warranty repair international rules. Crossing our fingers.

Hopefully they can call tag it via UPS or FedEx and get one back to us under warranty repair international rules. Crossing our fingers.