@yoderkl NATIONAL HERO!!!

Same batch as before, but this time I added some MakerJuice Green Pigment. 100 microns. Clear V3 Profile.

Cash Money.

the green color is amazing, though the quality of the clear seems better

It’s really looking good.

Can you try and print something big? I’m still interested in the dimensional accuracy(I can send you something that failed on photo centric resin).

Of course. Post here and I’ll print right away.

This is what I got cooking right now:

I will admit, the whole 100 mL thing in open mode is starting to become frustrating. There is a definitive line in the model where the print paused and resumed. This is most likely because I set it to print overnight and its been hanging there for maybe 6-10 hours before I can add more resin (the resin in the tank can be settled a little after that long too). I’m guessing if I just attend to the 100 mL warning immediately it won’t be as noticeable.

Another thing I’ve noticed is the glow in the dark powder I have is kinda working, but it does not mix that well. So like the bottom of the raft glows and nothing else ![]()

The line you are seeing is why I add resin while printing not allowing the printer to pause…

But that takes a magnet and special safety glasses.

Not exactly something I would recommend doing though…

I thought it automatically paused after 100 mL. I don’t think there is any way for the Form2 to sense the amount of 3rd party resin in the tank?

Sorry, I do this on a Form 1+ and rarely have Preform ask if I want to automatically pause the print. I just say no and add resin when I feel it is needed.

I do not know about the Form 2.

This time used MakerJuice Indigo with a pretty good pinch of glow in the dark powder. Clear V3 @ 100 microns with Modified Buck EP200:

No.I have never tried Clear V3 or Grey V3. but one time I printed the same model with resin clear V2 with clear v2 profile.but after I meassured it I see 0.3 mm error in z-axis again.

before I upgrade the firmware to the newest there was just 0.1 to 0.15 mm error in z-axis.but after upgrade I see 0.3 mm error.

even I downgrade to the last firmware to have 0.1 mm error again but it is still 0.3 mm error.

The bummers of using 3rd party resins… You never know what tweaks the firmware might introduce that could potentially disabled your resin from printing.

It seems to me like we are dealing with the same problem. This Bucktown resin I have been using drastically has suffered from too deep of cure depth. I mentioned a few ways we have solved that problem above, so you can try anyone of those if you would like, but if I were you, I would just print that same test cube in the same orientation with each standard resin profile and see if that corrects your slight cure depth issue. Did you contact the resin manufacturer?

@FredB Did you ever find an alternate source? Do you want me to ship you some to tinker with?

I’ve been working at work lately so I haven’t tried the new place.

Omnistab OB

http://igmresins.com/products/other-uv-raw-materials/additives

With this being a resin company they might be a little easier to work with. The full on chem companies want approval to sell you pretty much anything within reason.

Looks like they have some Photoinitiators as well… setting up account

IGM resins acquired BASF’s and Lamberti’s photoinitiator lines in the past year or two.

You have to purchase materials by the 200kg drum. Slightly lower amounts for P.I.'s.

Another option is to make a replacement control board for the printer with open source firmware.

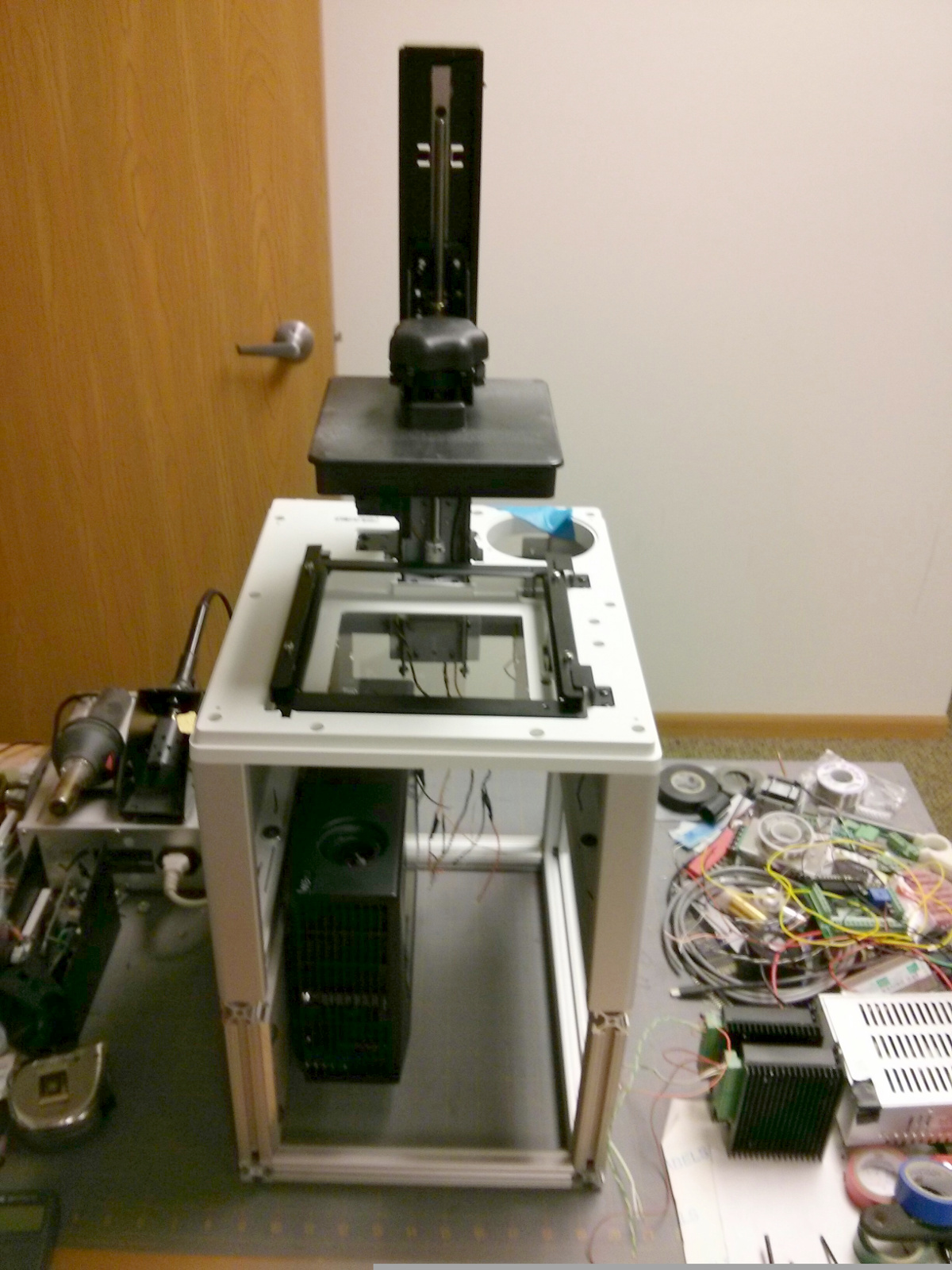

I’ve done it for a similar SLA printer and also did a DLP swap with the galvo and lasers.

Linuxcnc + Mesa FPGA and Mesa servo card for the galvos took a few hours. Spent some time tracing back the wiring and output types for the limit and home switches and replacing the stepper driven tilt mechanism.

Linuxcnc + LPT and BOB (break out board) with the DLP projector took about the same time.

Either mod will void the warranty.

Here’s the SLA printer with the galvos being driven by LinuxCNC, Mesa FPGA and Mesa servo card with the steppers driver from the PC’s LPT with BOB.

https://ibin.co/2rTeUifVo4aE.jpg

I think they have a section for samples that would work for experimenting. In the end it would be nice to get a company like Bucktown to produce resin with the blocker already added.

Most of us don’t want chemicals around the house or business. The blocker we’re talking about here is reasonably safe but I don’t want a ton of it around.

Some one just posted a qustion about 3Dresyns materials.

The materials are actually fairly interesting alone but, they have a tuning resin that is intended to change the cure properties. I think it has UV blocker in it and that would be great for the Bucktown materials. There are two options available.

Sending an email for more information now.