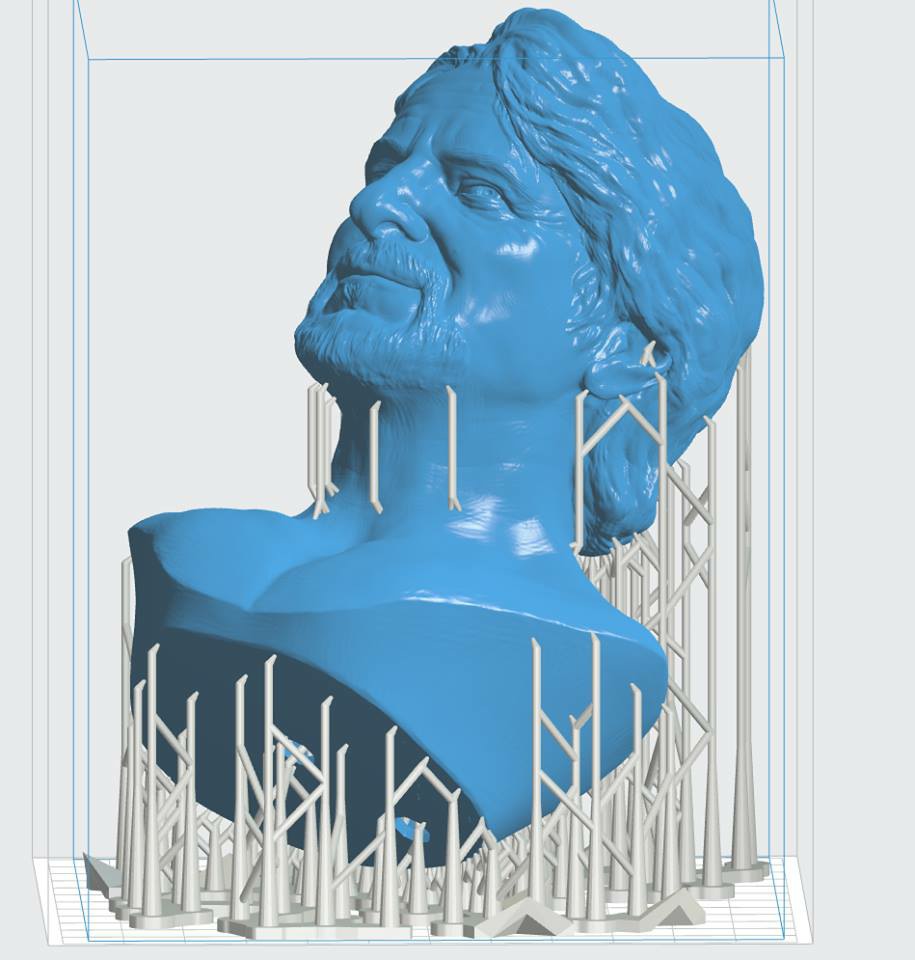

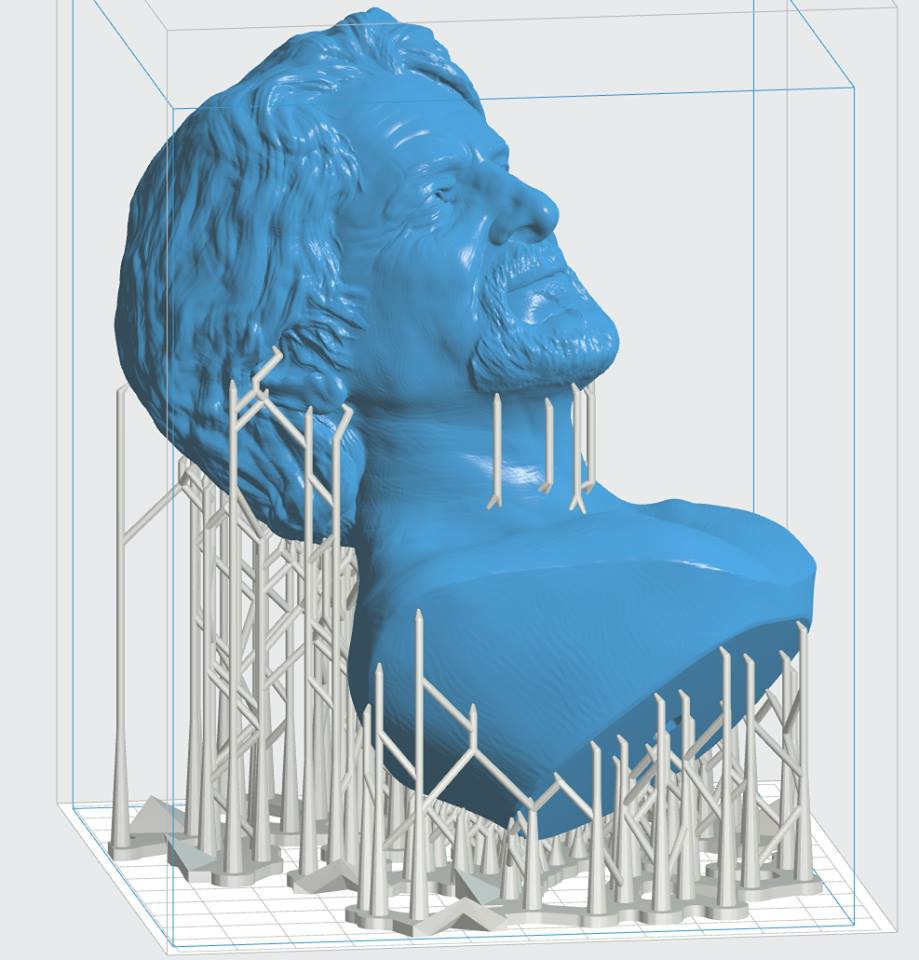

After cleaning the optics I finally got my first successful small prints on the Form1+ that I bought from a friend. Now I’m ready to run a fairly large part (~8x12x13cm) but wanted to show my preform build setup before hitting print to make sure my supports and orientation are ok. The model is hollow with 2mm thickness and two 3.5mm holes. Preform has an annoying habit of sending support branches through the drain holes to feed multiple internal contact points but I’m hoping this won’t cause any issues. I wish there was a way to prevent this since removing the supports manually doesn’t really solve the problem and also leaves me with too few supports inside the head.

I should also mention I plan to print at 50 micron in clear resin. The taller supports are on the hinge side of platform.

Mitch, note that you can add internal supports manually to keep them away from the drain hole if it’s causing blockage.

Jory

I would make at least all base supports the highest thickness if they are not already, to ensure it doesn’t break off. However it might be safer to print this in two parts (head and body) as it’s alot of resin to waist it it becomes a failed print.