hello all

I just started using this formlabs 1 I used to have a markerbot

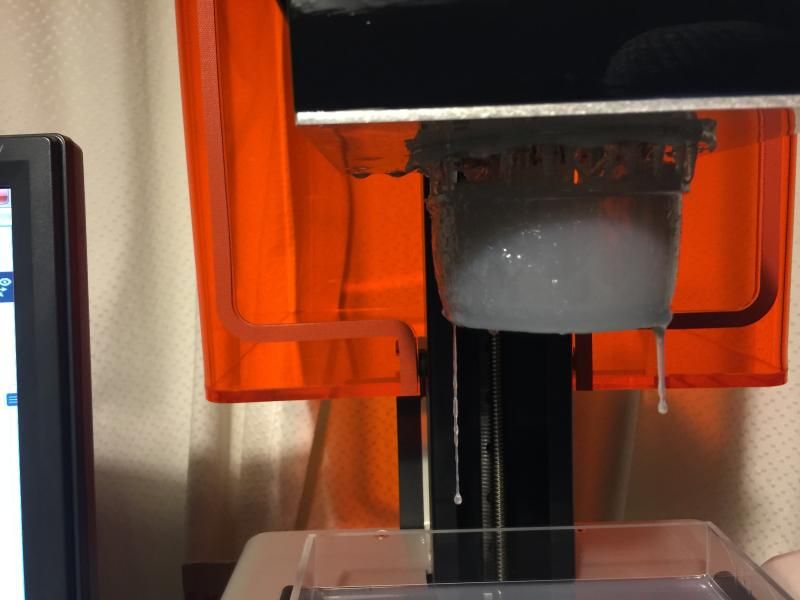

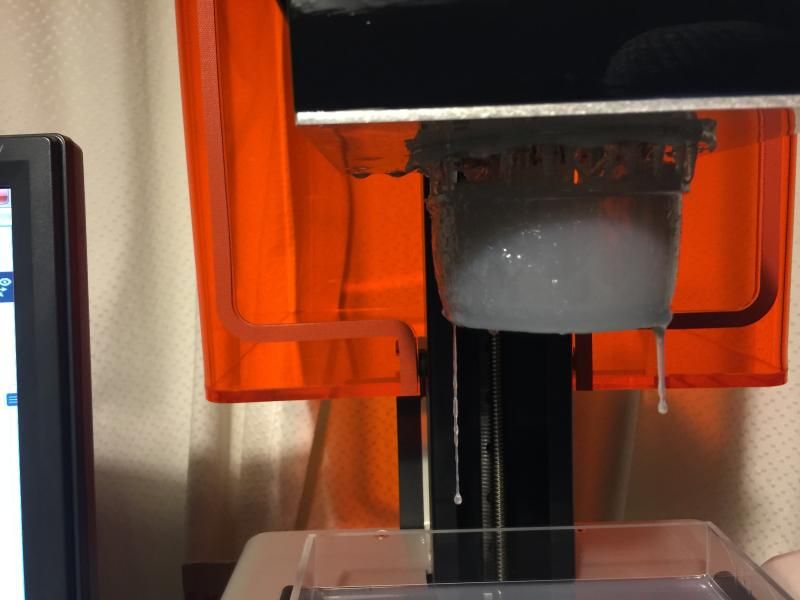

soo my issue my prints fail why is that? i’m trying to make a cap/cup

please tell me what i’m doing wrong

hello all

I just started using this formlabs 1 I used to have a markerbot

soo my issue my prints fail why is that? i’m trying to make a cap/cup

please tell me what i’m doing wrong

You need to reorient the part for starters.

Try the auto orient until you get the hang of how to do it yourself.

You should start with smaller items to get the hang of it. The larger you go the more issues can happen.

Thanks I did the auto orient, plus switched to clear ,the Grey I have seems funny…

if I was not on a time crunch I would play a little more I had issues with the base thickness just added more and seemed fine but didn’t notice the back said slide off

i’ll see how it looks in the AM

nope tried to print with the auto orient fell off ever time …

I also own a 'bot, a Rep1 Dual. The tricks I’ve learned over the years that lead to good prints on the 'bot mostly do not apply to the Form1. In particular, FFF prints do best when the model is oriented so layers are as large as possible. The Form1 wants exactly the opposite. A model of a Domino would print best on a Replicator if it was printed with the largest side down, parallel to the print bed. In the Form1, you’d do better with the Domino angled at 45 degrees.

Your first prints might have failed because you were printing square" to the build platform (this is what appears to be shown in the pictures you posted). The From1 has to peel each layer off the bottom of the resin tank. Large surfaces parallel to the build plate are harder to peel cleanly, and they put a lot of pulling stress on the layers already printed and the print supports and base those layers are attached to. Based on what I think I see in your picture, this sounds like what happened.

After the first print, you probably had stuff stuck to the bottom of the resin tank, and lots of floating debris in the resin. If you didn’t remove that stuff before trying the next print, things would only get worse. You tried the automatic orientation feature and it still didn’t print. But that would have been the likely outcome if you hadn’t cleaned up completely from the previous failures.

You tried Clear resin, did you go back to having the model “square” to the build platform? If you did, you may still have the same problem.

Also, did you shake the resin bottle before pouring it in to the resin tank?

The auto-orient feature in PreForm appears to pretty much just randomize the orientation of the model. If you hit the “Orient All” button repeatedly you get a different orientation each time. If PreForm were actually “computing” an optimal position, it should end up with the same solution each time. It doesn’t. And it doesn’t always give you a good solution. I’ve found that using low density/small point size supports works best for the things I’m printing. Supports generated after using the “Orient All” button often leaves areas of the model unsupported (highlighted in red in the 3D view). Manual orientation works much better for me. I try to orient the model to minimize the size of contiguously printed areas in each layer. Perfectly parallel to the build plate is the worst orientation, but manual orientation is better than auto, IMO.

clear did nothing but stick to the silicon …

i’m switching back to gray and I did shake it very hard! for a few mins and I did use a paint filter …

I will try again tonight with grey but so far I find it hard to believe this printer is any good so far …

It seems you need a formlabs tech to come to every ones house with issues…

Side note I just got access to a GIGABOT and it a monster!

The first print I tried failed, but it was complex and I did not understand the way the printer worked yet, I saw an area that was not fully supported but figured it was OK. It wasn’t. Since then, I’ve done >2-dozen prints, a number of different things as well as some items I’ve printed multiple times. I haven’t had a single issue (though I haven’t gone back to retry that original print, it uses a lot of resin). I had a lot of debris and stuff stuck to the bottom of the tank after that first failed print, that I had to clean. But I have not been very religious about cleaning the tanks since. I figure if the last print didn’t fail, there’s nothing to clean. I did a lot of my initial prints in Grey resin. I’ve done one print in Flexible, and a half dozen with Clear, and each has been excellent.

Hard to say what your issue is, but I can say at least in my case the printer does exactly what FormLabs says it does. Hopefully solving your issue is just a matter of gaining some experience. You should consider printing something smaller first. Printing something big that used most of the build volume was my mistake, my so-far one-and-only print fail.

I Tried to print something of a quarter and it just falls off the supports Due the prints coming off very soft its seems

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.