Hi @Ante_Vukorepa ! I’m an engineer on Dan’s team here at Formlabs. I wanted to get back to you on some of your questions about the printer’s laser scans. We refer to the process as the “fiducial scan” and the panel with the photosensors as the “fiducial board” so I’ll use those terms throughout.

First, just to clear up some confusion—neither the fiducial scans, nor the sensors that are used for them, are new or temporary, and they’re not going away either. Every Form 2 ever made has had a fiducial board and (apart from a few beta releases around launch) every firmware we’ve ever released has included fiducial scans on every layer. I’m not sure what @fantasy2 saw, but I’m afraid they must have been mistaken when they said a new printer was lacking those sensors; that’s just not the case. Every print you (or I!) have ever done on a Form 2 included these scans.

Fiducial scans are an important part of the printer’s optical system, and doing them every layer really does benefit the results. For a variety of reasons (thermal expansion of the printer components and frame, wear and tear on the galvos over time, electrical fluctuations, and more) the galvo mirrors that aim the laser will drift away from their initial position. Fiducial scans let us detect and compensate for that drift and keep the laser on target, to ensure that your part prints as designed. If the fiducial system breaks down, layers won’t always line up from one to the next. This might result in a strange “wobbly” quality to the part, or in extreme cases, parts will start skewing across the platform into a curved or parallelogram shape.

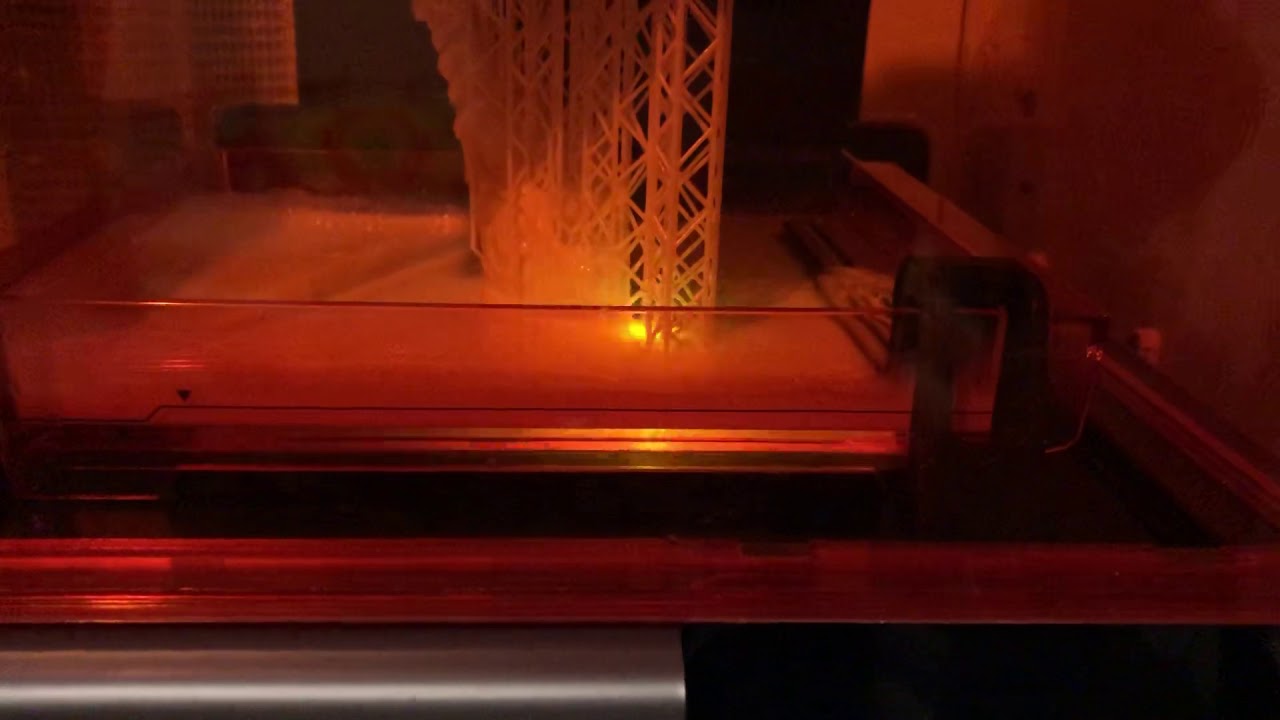

The fiducial sensors are located at the corners of the optical window—or more specifically, outside those corners. When we aim the laser at the fiducial sensors, the laser spot itself is well away from the window or the tank. Although some scattered stray light is visible coming up through the tank, it’s a tiny fraction of the laser’s total energy, so it shouldn’t be an issue for your resin. If you do notice any half-cured gunk in your tank (with no print failure to explain it,) then please let us know—it could mean that your particular printer is having an issue or aiming at the wrong spot when performing a scan.

As for your print time discrepancies: although fiducial scans do add a tiny bit of print time—and, as you say, the time cost will be a greater percentage of the whole the smaller the surface area of each layer—that time is only a few seconds per layer and should really be negligible in almost every case. We haven’t changed fiducial behavior lately, so the scans are only adding as much to your print time as they always have. There are a lot of things that can extend print time, but by far the most common reason a print might be longer than PreForm’s estimate are pauses for tank level sensing and for resin dispensing.

Because these parts of the print are non-deterministic and can’t be calculated beforehand, they’re left out of PreForm’s estimate, and will always result in a print time slightly longer than the prediction. On a healthy printer with a full cartridge of resin, the time difference will be about 5-10% (and always has been). If the printer’s level-sense system is having trouble (for instance, if there’s resin on the sensor panel) or if the cartridge is getting low and dispenses slowly, the discrepancy will grow. We’re currently working on revising our estimates to include an approximate allowance for levelsense (based on averages of similar prints) which you can try out by opting in to our beta program, but since it’s based on global averages, it won’t help if your particular printer is having trouble. PreForm simply has no way to know that that will happen when it calculates the print time.

I see we already suggested opening a support case to check on the strange dispense motor behavior you saw (which definitely isn’t normal)—if you did so, then I’d definitely encourage you to check with your support agent about what might be affecting level-sensing or dispense on your printer and causing these extra-long prints. I can tell you that I’m confident that fiducial scans aren’t the source of the trouble.

I hope this helps! Please let me know if I can explain anything else and I’ll be happy to keep the discussion going.