Like many of you I lay in bed at night thinking up crazy  new ideas and uses for various upgrades to things in my life. Last night I had one that I thought would be worth sharing.

new ideas and uses for various upgrades to things in my life. Last night I had one that I thought would be worth sharing.

I was thinking about buying some high temp resin to create a new type of extrusion cooling fan shroud for my FDM 3D printer. The ones I have created with ABS all tend to melt and deform near the tip do to their proximity to the Hot End.

The ones I have created with ABS all tend to melt and deform near the tip do to their proximity to the Hot End. Then I had the idea of making a new design of cooling fan shroud that actually made contact with the Hot end. That way the cooling air can be directed in detail.

Then I had the idea of making a new design of cooling fan shroud that actually made contact with the Hot end. That way the cooling air can be directed in detail.

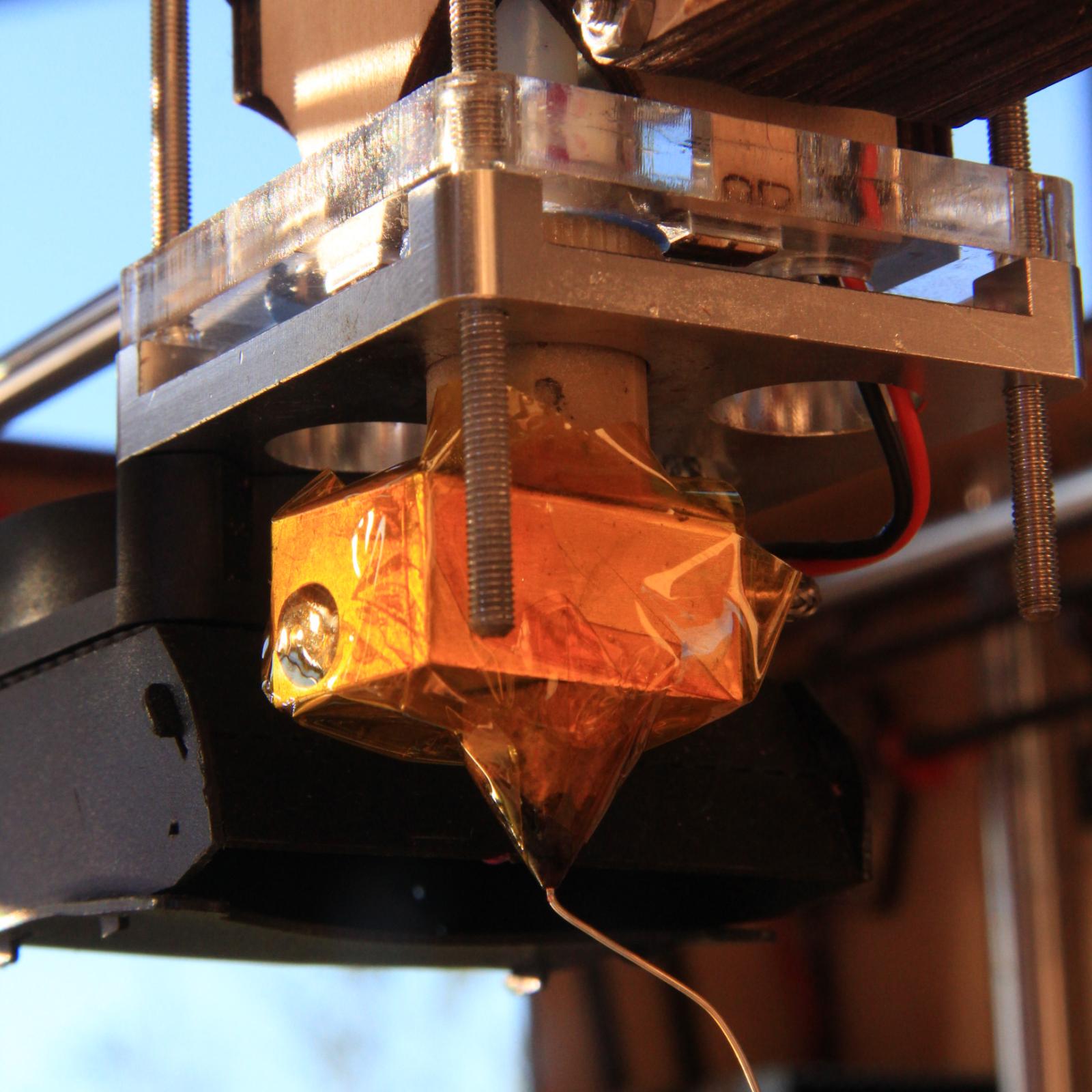

Then I switched mental gears and started thinking about how I have seen a lot of people wrap Kapton tape around the hot end of their FDM Extruders. See the image for an example.

They say it helps to regulate the temperature in the melting chamber by insulating the surface from air currents generated by the Extrusion cooling fans. It also helps to keep the the Hot end clean.

So what if I took some High Temp Resin and applied it to the hot end then cured it manually with a 405 nm UV light? Maybe add a few layers. I imagine it would give a nice smooth finish. I also imagine that I could control where the resin goes and where it does not. For example I could get it really close to the tip of the nozzle without getting on the tip. But I could also keep the resin off the heat element wires if I chose.

High Temp is good up to 289 C. The highest I have ever used my FDM extruder is 250 C. So the temperature should be within normal use limits.

Here is where I ask for feedback. I don’t have high temp resin yet. I will eventually. Those of you that have experience high temp might be able to tell me if either of these ideas are worth trying or not. I know High Temp is brittle. Would it Crack as the Hot end Expands and contracts with temp changes? Would it work as a cooling fan shroud?