Could someone guide me on how this model should be orienten on a Form 3 for optimum, overall surface quality?

It will be printed in clear.

(I’m sorry if I posted this in the wrong section)

Lily58_case_Plate.stl (181.8 KB)

Could someone guide me on how this model should be orienten on a Form 3 for optimum, overall surface quality?

It will be printed in clear.

(I’m sorry if I posted this in the wrong section)

Lily58_case_Plate.stl (181.8 KB)

You want to tilt it over on its side a bit, move it maybe 30 or 45º. That should guarantee you only get support contact points on the corners of all the openings. I would keep it with the side you have up, up. That long spur on the right side shouldn’t need any supports at all…

I would print it flat on the build platform, and account for the 1/2mm over compression by stretching it 1/2mm vertically.

This way the top and bottom surfaces will be perfect, without any support marks.

Flat isn’t an option as it’s a fraction to big for that.

Like this it says it needs more supports? But printing like this will be a nightmare to clean up afterwards.

How about his?

Or this?

That did not turn out so well. The lower left part on the image in the previous post came out bent(!) and I have lines all over the print.

It was printed in Clear v4 Beta at 100 micron on a Form 3 with the latest firmware and PreForm.

What’s the size of that model?

try growing flat on the bed just have to compensate for the first few layers being compressed so it would be a fraction thinner

It’s a rather big, but flat model.

I printed it standing like this and that turned out much better, still had the striping though. Also the cutouts were a fraction to small, which I guess comes from they sagging a bit as the top part was horizontal and printed as an overhang.

Now I’m printing the 2nd half (mirrored copy) in another angle just to test and learn. Lets see how this turns out.

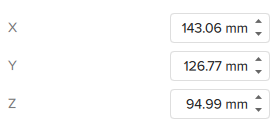

Are you sure those dimensions are correct? For one, if the model is only 143.06 mm long, it should fit on the build platform of the Form 3, which is 145 mm. Also the thickness of the model in proportion to the rest of it is only a fraction, but you said it’s 95 mm which would make it nearly as thick as it wide.

Did you look at the measurements of the model when it was oriented at an angle in Preform? That might explain weird numbers.

I used your snapshot of the model laying flat on the platform and replicated it and the model appears to be approximately 153 x 116.3 x 7 mm

Anyway, the reason I’m asking I was curios if it would fit other printers, and it does fit the Anycubic Mono.

The point I’m trying to make is that we all have a “go to” printer we use 99% of the time, but sometimes it’s worth having other tools at your disposal for those times when the “go to” printer can’t do the job. I still have a FDM printer for those times when I need to print something out of more resilient materials, like ABS.

You are of corse absolutely correct - I took the measurements from the oriented model.

My last attempt was a success, it came out much nicer. I washed it, let it dry, took off supports and cured it, only to have it warp while curing

So lesson learned I guess, leave supports while curing flat objects.

Just a caution to fellow forum users, but a first-time post from a new user with an embedded link asking that you click it should probably not be clicked.

If a user wants an opinion on something, it is trivially simple to drag/drop a picture in the forum, or even use screen grab with “ctrl-V” to paste the capture in to the thread.

This topic was automatically closed 182 days after the last reply. New replies are no longer allowed.