Pia,

Very good question, and unfortunately I do not have the answer you are looking for. Here is some more information that they gave me.

Obvious Preface: I am not qualified to properly interpret these slides.

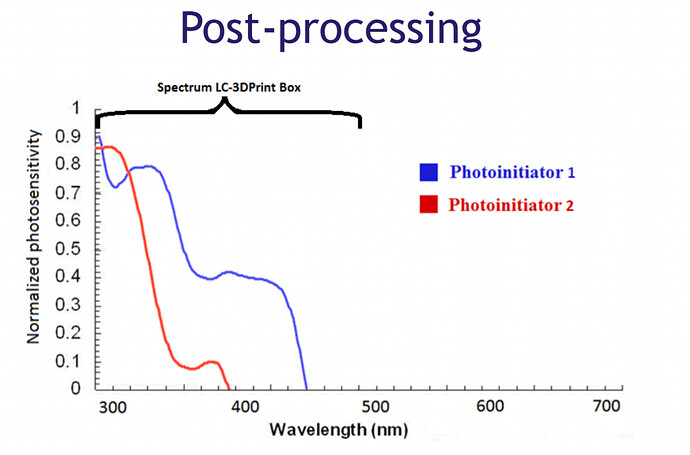

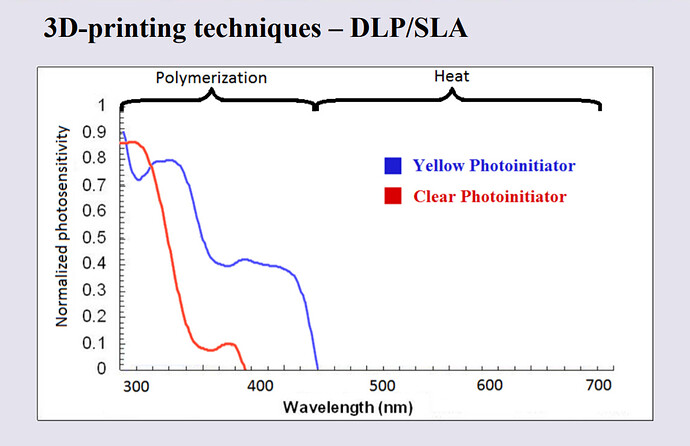

But It seems like this resin has two photoinitiators, and it appears as if “Photoinitiator 1 / Yellow” is indeed, photosensitive at 405 nm. “Photoinitiator 2 / Clear” appears as if it would never begin to polymerize with a 405 nm laser. Maybe the highest wavelength it is photosensitive at is 375-380 nm, and even then, it is just barely photosensitive.

In the documentation they give you with your purchase, the recommended post-cure wavelength is 315-400 nm, which is a slightly broader spectrum then the “365-385 nm” listed on their site, albeit, it is referring to post curing and not actual printing.

My best guess would be that, at least one of the two photoiniators is getting catalyzed by the 405 nm laser (apparently enough to physically create a properly bonded model). Probably ideally, multiple wavelengths or a spectrum of wavelengths emitted at once would achieve the most photoiniation, and the least amount of complications during printing. I am also guessing that with my CureBox from @pmcgarr which post cures at both 365/405 nm, I might be polymerizing that other photoinitiator so the final product would be similar to a splint printed with DLP.

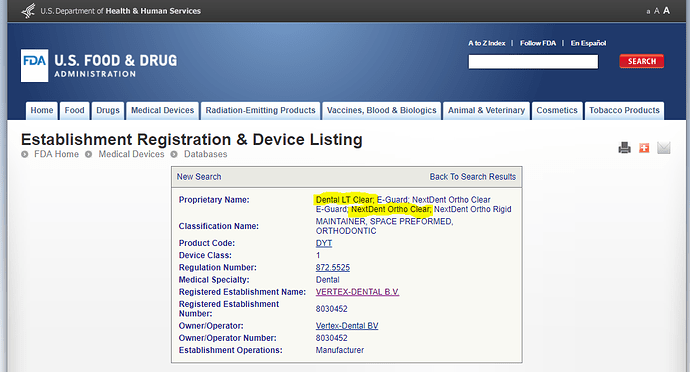

Additionally, I was doing a little research, and I noticed that the company that actually makes the NextDent resin (Vertex Dental B.V.), sells it as a private label as well. When I dug a little deeper, I saw that the product name “NextDent Clear Ortho” was synonymous with Formlabs upcoming splint material, “Dental LT Clear.”

Again, I am no expert on these things, but it seems to me, that as far as the FDA is concerned, they are the same product. Following that logic, if Formlabs is releasing their “Dental LT Clear” aka “NextDent Ortho Clear” that has been tested by Formlabs with their own machines and quality control, then theoretically we don’t have to worry about the specific mechanisms of photoinitation, as they feel it is curing properly. Might be a stretch, but that’s all I got so far!

What do you think?