I’m hosting an Additive Manufacturing hardware meetup in around 2 weeks in Vancouver, Canada (Additive Manufacturing with Ember Prototypes · Luma).

I’ll be bringing my Form 4L to the event and hoping to print something in real time.

Just wondering if anyone here has a cool, large example print of a real, functional part that’s pre-sliced and ready to go on the machine that I could consider printing onsite. It can either be a single large part, or several parts arrayed over the build plate.

Ideally the print would take around 3-4 hours so it can complete by the end of the event. Thanks in advance!

2 Likes

Hey @leonhart88 !

We have two pretty great prints to share for printing in clear: 1 is a Shoe compression mold and the other is a batch production run of medical mallets. Both around 4 hours.

[Note for functional mallet usage we recommend ideally printing in durable or biomed durable].

Hope these help!

Mallets 4 hrs_4L.form (5.1 MB)

Shoe Compression Mold 4 h 8 m.form (1.5 MB)

2 Likes

Thanks @verdugod! I’ve been working with Jillian from support and we chose to go with the mallets so everyone can take one home

1 Like

BTW was that shoe mold printed flat!? I am very impressed if yes…I haven’t tried huge flat parts like that in a very long a time

BTW was that shoe mold printed flat!? I am very impressed if yes…I haven’t tried huge flat parts like that in a very long a time

1 Like

With supports! Would be pretty difficult to get that sized print off, direct from the build platform if it isn’t a flexible platform.

2 Likes

Hey @leonhart88 I’m mistaken! I just learned from @henryqiu that the shoe mold was actually indeed printed flat on BP without supports (!), there are drain holes for cupping and therefore don’t require supports anywhere : )

4 Likes

Crazy! I will have to try it another time. Currently have the mini mallets ready to go

3 Likes

Mallets came out great

After this initial print, I actually modified the .form file to fit even more pieces on there and make it easier for part removal as well

3 Likes

Whatta batch! They look great!!

1 Like

Hello Leonhart88,

Could you share how you post process them?

I can’t get our products as clear as that, they always look dull after washing and curing.

1 Like

These parts had zero post processing. Just removed from the build plate and washed.

Clear V5 (on the Form 4 and 4L) have better clarity than Clear V4.

Also, anecdotally, thicker clear parts tend to look clearer than thin walled clear parts. I think this has something to do with layer alignment and registration (ie. thin walls are less stiff and move around more so the layers don’t line up as perfect causing optical abberations)…so it kind of depends on geometry too.

4 Likes

Are you washing with IPA or with Resin Wash Solution?

We got the machine with Resin Wash Solution so we started with that.

After washing there would always be a sticky layer remaining and after curing that would turn dull.

Today we switched to 100% IPA and immediately better results in clear resin.

1 Like

Interesting…I’ve always used IPA because I can distill it with my solvent recycler!

1 Like

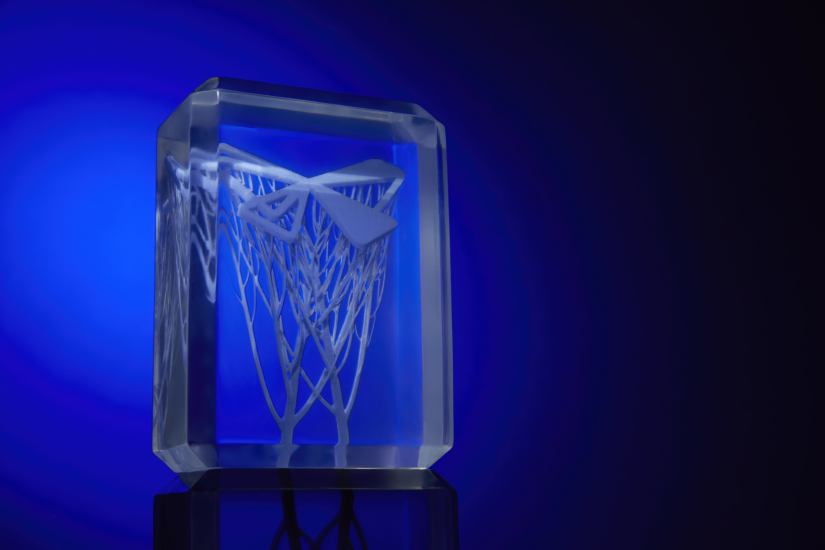

At Steam Factory, this is one of our go-to samples in clear

Built directly on build platform. No supports (internal or external). Completely fluid-tight.

4 Likes

This would have been fun to print at the meetup

2 Likes

Hit me up next time!

We’re in the process of revamping everything at Steam Factory. Hopefully have a curated library of great parts to share by this summer.

3 Likes

Love this @SteamFactoryLLC ! Microfluidics, DfAM and clear at their finest

2 Likes

I’ve manufactured very similar parts for a local company, cleaning one of them was a true nightmare once.

1 Like

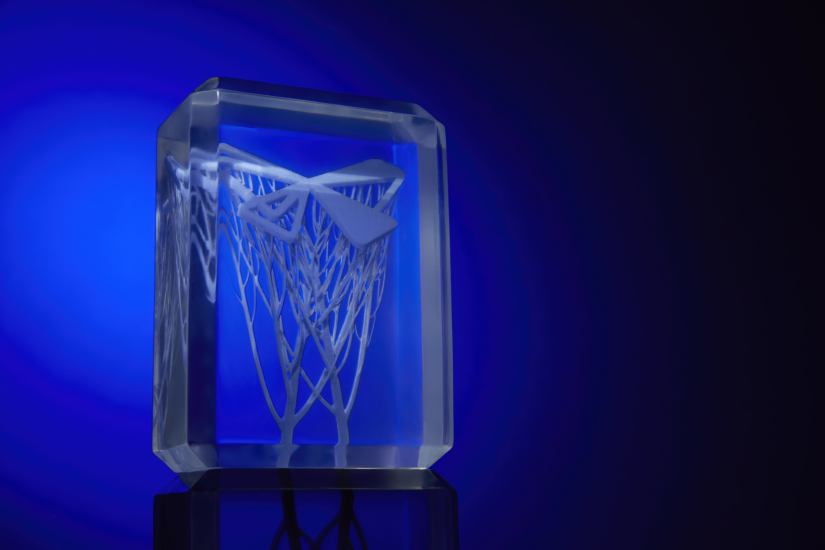

If you’re interested in microfluidics, from an aesthetic perspective, you gotta see this application of the team at Nervous System who used it for an incredible looking trophy for the Formlabs Impact Awards in 2022.

Their design was informed with their work designing vascular networks. They prototyped filling channels with ketchup and eventually switched to resin or the final ones

Nervous System’s design for the Formlabs Impact Award

6 Likes

![]()