Hello all, our group is trying to print some challenging lattices using Alumina 4N resin (Form 3, default alumina settings). Ive included pictures of the model, we are aware it might be pushing the limits of the material, but any feedback on printing techniques helps.

This is one of our lattices (below). Our first print (1/4th of a unit cell, also below) went well. All subsequent prints of partial and complete unit cells in alumina have failed by the same mode. Our parts seem to lose adherence to itself at multiple layers (also pictured), we have been finding recognizable and near-complete chunks of the parts that fell in the resin tank. We haven’t changed any settings, using the same model, in a few different areas of the printer. Any feedback on how to improve prints of alumina or deal with this specific failure mode are appreciated. We’ve been combing through the written guides and its not helped yet.

Full unit cell

1/4th unit cell

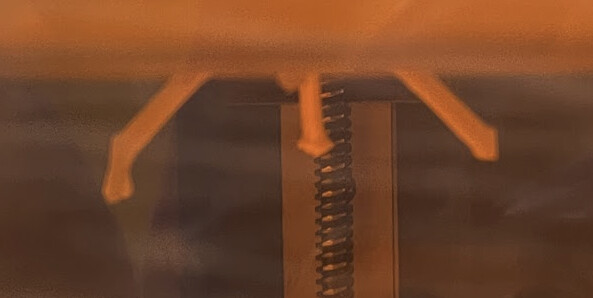

Failed full unit cell (note: each of the “legs” failed at a different layer, sometimes dozens apart, other versions of this same print are even more drastic).