Not sure when this changed, i’ve been away for a while and haven’t used my Form2, but i’m noticing that the peel now first does a SHARP Z move, about 2-3mm up, then the vat slide.

This is horrible, and way worse than the original peel strategy of synchronous Z + slide, especially on resins that are more vulnerable in green state, like Tough (v1 and v2 at least).

I’ve had chunks and slivers straight out ripped out of a print by the support attachment points thanks to this “improvement”. Nasty. No idea who thought this is better, but there must be a reason for the change.

Anyone else finding this problematic?

So you’ve seen this in Tough v2 in particular? What PreForm version and what general part size and rough layer number are you seeing this?

Tough v1. I believe v1 and v2 are about the same w/ respect to sensitivity to peel (i might be wrong).

Note also that my v1 is now pretty old (not sure what the expected shelf life for v1 @ room temp is, though).

General part size - about 5 x 5 cm, cross section around 5 mm^2.

Number of layers - about 500 @ 100um.

Note that rips did not occur in areas with no supports. The part partially delaminated at the support interface points.

With all that said, i don’t get the new strategy at all - what’s the purpose of the sidewise move at all now? You could just rip it off with a Z motion and be done with it, it’d be essentially the same.

Edit: forgot - latest windows Pre-Form.

1 Like

Can you clarify, the relevant layer is roughly 5 cm square, or 50 mm x 50 mm, so the area would be on the order of 5 cm * 5 cm = 25 cm^2 or 50 mm * 50 mm = 2500 mm^2?

It sounds like your part at the layer of interest is partially on supports and partially connected to earlier layers of part. Is that correct?

No, no, the total bounding box is about 5 x 5 (x 5) cm, the object itself never has a cross-section bigger than 0.5cm^2 (accounting for the slant of the object’s printing orientation).

There is no single layer of interest, this happened on multiple layers throughout the object (total 500 layers tall).

Additionally, i’ve just tried printing a relatively big object with a thin cross-section as a test - an iphone case - so the peeling forces are minimal (yes, i’m fully aware Tough is bad with thin shells, i just wanted to see what will happen). I stopped it mid-print when the shell fell apart, but what i found elsewhere is… not very good.

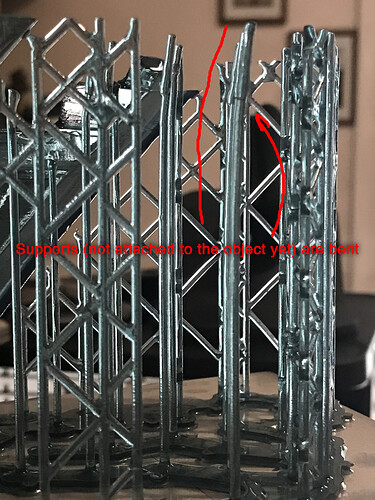

I found a few tall supports that managed to partially deform/rip the edges of the base, and a few supports that were deformed - note that these didn’t even reach the object itself yet. The supports themselves were malformed from the peeling forces.

The object itself was heavily deformed already at its first 100 layers or so, with noticeable striations from the peeling.

Now, either the peel sucks, or my (admittedly old) batch of Tough V1 sucks, i don’t think there’s a third option

I’ll try and take a photo of the bendy (standalone) supports tomorrow, it’s past midnight at the moment here.

Thanks. I’ll investigate more. For the record, I don’t believe anything has changed in this regard in quite some time.

1 Like

Here come the photos… All of them taken while still on the build platform, untouched.

Note that i’ve received a response from support in the meantime, saying that the batch of Tough i’m using definitely is out of date (year old, so just expired). That does not explain the odd peel (Z lift, then slide).

I’ll try and capture a video of it in action later tonight.

1 Like

Here’s the vid.

It’s a little hard to see because the movement is very small (a few mm), but if you look closely, right at the beginning of the peel, you’ll see Z do a quick yank up, then the slide, then the Z lift to safe distance for wipe.

That is not how peel used to behave way back. It used to do a synchronized Z+slide move, and a slow one. I’m guessing this is some kind of a bodge to increase printing speed. With the new peel, the slide is completely superfluous, the Z yank rips the printed layer off the PDMS.

During the base buildup layers (the slow ones), the exact same behaviour can be seen, except slower, and with a longer Z yank at the beginning.

Note: if you can’t see the Z yank, try listening for it (you can hear it right before the slide), or try using a piece of paper, or - try scrubbing the video quickly around when it happens (the increased speed makes the motion more obvious).

3 Likes

@Ante_Vukorepa nice pick up, the contrast between old and “new” peel is explicit - if you look at another video of yours from Jan 2016 - https://www.youtube.com/watch?v=Etgnz-0UCCE at around 0.27s - 0.28s and play at 1/2 speed or slower. The synchronised slide and lift is very obvious, not least because of the clear peel thunk you can hear.

A couple of points though - first I don’t think the change is recent, as you noted in the OP you’ve been away. I’m not sure I really noticed it when it changed, I think it was last year though.

Second is that I don’t think the lift-then-slide peel is significantly more aggressive. One of the first observations I can remember about my new F2 - was thinking the slide seemed a bit pointless; the “thunk” and visible vibration/shock of separation seemed every bit as loud and dramatic as on the F1+ (if I prewarmed the resin for it). The most important improvement in the F2 peel seemed to be just heating the resin hence reducing it’s viscosity.

Listen to the peel thunks on your Jan 16 video with the synchronised peel and lift - still pretty hefty.

However - agreed - the slide does seem obviously superfluous now that you’ve pointed out the changed peel sequence.,

Maybe there are some edge cases the slide helps with? like if the yank is not enough to do full separation? and the bottom of the tank and silicone just flex at first? I’m not sure the yank is 2-3mm is you suggest - it seems smaller than that to me - although admittedly I haven’t done a print for a while. In any case a synchronised yank and slide is surely better if there are any edge cases that might benefit from the slide…

3 Likes

Hi there,

I’m the one responsible for the peel changes you’ve observed, and I wanted to offer my perspective. You’re certainly not the first person to notice them, and not even the first to call them into question  , so no hard feelings from my end. In fact, I applaud your keen eye and attentiveness.

, so no hard feelings from my end. In fact, I applaud your keen eye and attentiveness.

First of all, the printer has always lifted the build platform a small amount before sliding, and then to continued to lift while sliding. You may not have noticed it before because the speed of that initial lift used to be slower. It’s present in the video that @KevinHolmes referred to, but it’s difficult to see. You can get a better look in this review of the Form 2, which shows a nice close-up of the printer peeling at 0:54 (slow down to quarter speed for the best view).

The changes you’ve noticed were introduced over a year ago (spring, 2016). They modified the speeds and distances of the motor moves in the peel, but not the underlying sequence. One of these changes was to speed up the initial lift, but other changes slowed things down elsewhere. Overall, they ended up decreasing peel forces while keeping print time more or less the same. As a result, the “thunk” or “pop” sound while peeling that Kevin mentions is now far less common than it used to be.

I’m sorry to see that you’ve been having some print failures. I encourage you to try out a fresh batch of resin and let us know if it helps.

Hope this sheds some light on what’s going on. If you have any additional questions, I’ll do my best to answer them.

Robert

4 Likes

Robert is right. He sped up that initial lift a while ago; it actually lifts less far than it did in PreForm 2.0.0 (late 2015) but it generally does that lift faster than it used to, and so it takes much less time. Between PreForm 2.3.0 (April 2016) and today, those details haven’t changed much. Exactly what the printer does is based on a number of factors, so the behaviors shown in the videos the Ante and Kevin posted could even be different layers of the same print.

As for @Ante_Vukorepa’s initial issue, I agree: I suspect the old Tough V1 resin.

2 Likes

Cool, thanks for the replies everyone!

I think what happens is - while the overall deformation due to peel (the “skew” that prints sometimes get from the peel) is likely smaller now, the tradeoff is that for resins that have an extremely soft green state (like an old Tough v1) the effect is not as good, as the faster initial Z yank can occasionally make them break/delaminate.

Obviously, using an old batch of resin (that’s very soft to begin with) is an extreme case, and not normal m.o. so tradeoffs are to be expected.

At least now i know i’m not going crazy, though

Regarding the “thunks” - i’ve never really experienced any thunks with Tough v1 (way back when it was fresh, or now). It’s simply too “plastic” (deformation-wise) and too soft. Even when taking it off the platform, it’s never a violent detach, it just gently peels off.

Finally - one remaining question @Robert_Gambee: is the slide even necessary now? If it is, is a full slide necessary? I’m guessing positioning might be a problem without moving the tray all the way to the stop and back (in case of missed steps)…

Some additional thoughts:

Not even sure the thunk is a legitimate gauge for the peel force - it occurs after the fresh layer releases from the PDMA, and as such actually indicates the force of release, the “spring-back” if you will.

Let’s say you do a Z lift of only 0.5mm, but extremely violently - the print might not detach at all at first. What happens is, the PDMS and the print deform, until they yield or detach. Now let’s say you start sliding or moving Z further, but slowly - the object finally detaches, with a very low peel force. BUT, it was subjected to a much greater force at the beginning, due to the high acceleration/jerk of the initial yank. There is no thunk, and, for a highly elastic / stronger green state resin there are no side effects, probably.

But, for a softer and more plastic resin, the initial yank caused permanent deformation or breaks, even though the final release was of a (percieved) lower force.

1 Like

That all makes sense. While there are always things we could improve, there is also a balance among forces on the part, print speed, and reliability: after all, if a part somehow doesn’t detach then when the part is lifted out of the way of the wiper, the z motor would stall and the print would fail, which isn’t acceptable. I hope that satisfies your curiosity. If you see issues like this in the future, please continue to bring them to our attention.

PS: The part you DM’d me is printing in Tough V3 right next to me as we speak.

3 Likes

Ben shared the photos of his Tough V3 print and they look completely normal.

I guess V1 exacerbates any shearing forces from the peels.

Which brings me to this…

Turns out i was way off in the assumption the initial Z move is what causes the tears etc. on soft resins. It’s actually - THE SLIDE!

I left an object with a big fat cross section to print an hour ago, just to see what happens (going to dump the resin anyway pretty soon, and if the tank’s PDMS layer gets torn, i’m getting a new one anyway). As it turns out, the thunk occurs midway through a slide. Which is scary.

Not the intensity of the sound, mind you, but the fact the tank moves sideways A LOT before the layer detaches from the PDMS. Which means the initial Z move doesn’t really manage to detach it at all, and there’s a huge shearing force on the supports until it finally (and audibly) detaches. I’m guessing this is, again, not a problem with more rigid resins, but with the old Tough V1 , it’s malleable enough supports bend and rip chunks out of it before the (relatively much much stronger) adhesion is overcome.

Scary, no?

Anyways, i guess you can consider this “case closed”, i’m just playing with it more out of curiosity.

2 Likes

Just a small update (in case anyone’s following)…

Turns out the old Tough is super hit-and-miss.

Basically it’s like it being old, combined with the changed peel, keep it right at the edge of spec/usability.

Here’s a weird print (bizarro support slippage during peel):

And here’s an okay print, after some sanding and clear matte finishing (thing:2234489):

1 Like

Just a tiny update, in case anyone finds it interesting…

Found a cartridge with some leftover gray resin (v2) while cleaning/tidying up and decided to give it a spin. It’s as old as the Tough v1 i’ve been commenting on in this thread.

Turns out there is zero issues with that one, as far as peel, peel induced stresses and deformations go. So it seems like the new peel just exacerbates issues caused by resins already very bendy in green state / whose photoinitiator is starting to go bad.

1 Like

, so no hard feelings from my end. In fact, I applaud your keen eye and attentiveness.

, so no hard feelings from my end. In fact, I applaud your keen eye and attentiveness.