John,

Has there been any testing using your high deflection temperature resin for injection molding?

I am thinking of trying it as the HT resin from form labs works good but its a bit brittle.

Just ordered some for testing

One thing that I’ve found for injection molding is to mount the detail in the mold frame along with two part silicone (use mold release to keep it from sticking).

The silicone takes up any small gaps and helps keep the detail from cracking.

So I tried the 3DResyn UHT HTR with black pigment today.

Using the recommended clear V2 profile, I had massive under curing and parts breaking partially during printing. Then I did a 30 minute cure in the form Cure and followed by putting them in the oven at 150 Celsius.

The material became extremely brittle at this temperature. Standard formlabs resin performs much better. I’m not sure what’s going wrong here, but so far it’s no better than the photocentric high tensile resin.

I’m now trying to print with it in closed mode. Will do more printing tests and let you know.

FredB,

Thanks for the tip. I do use 100% silicone oil to dress the mold and then anneal to re leave stress.

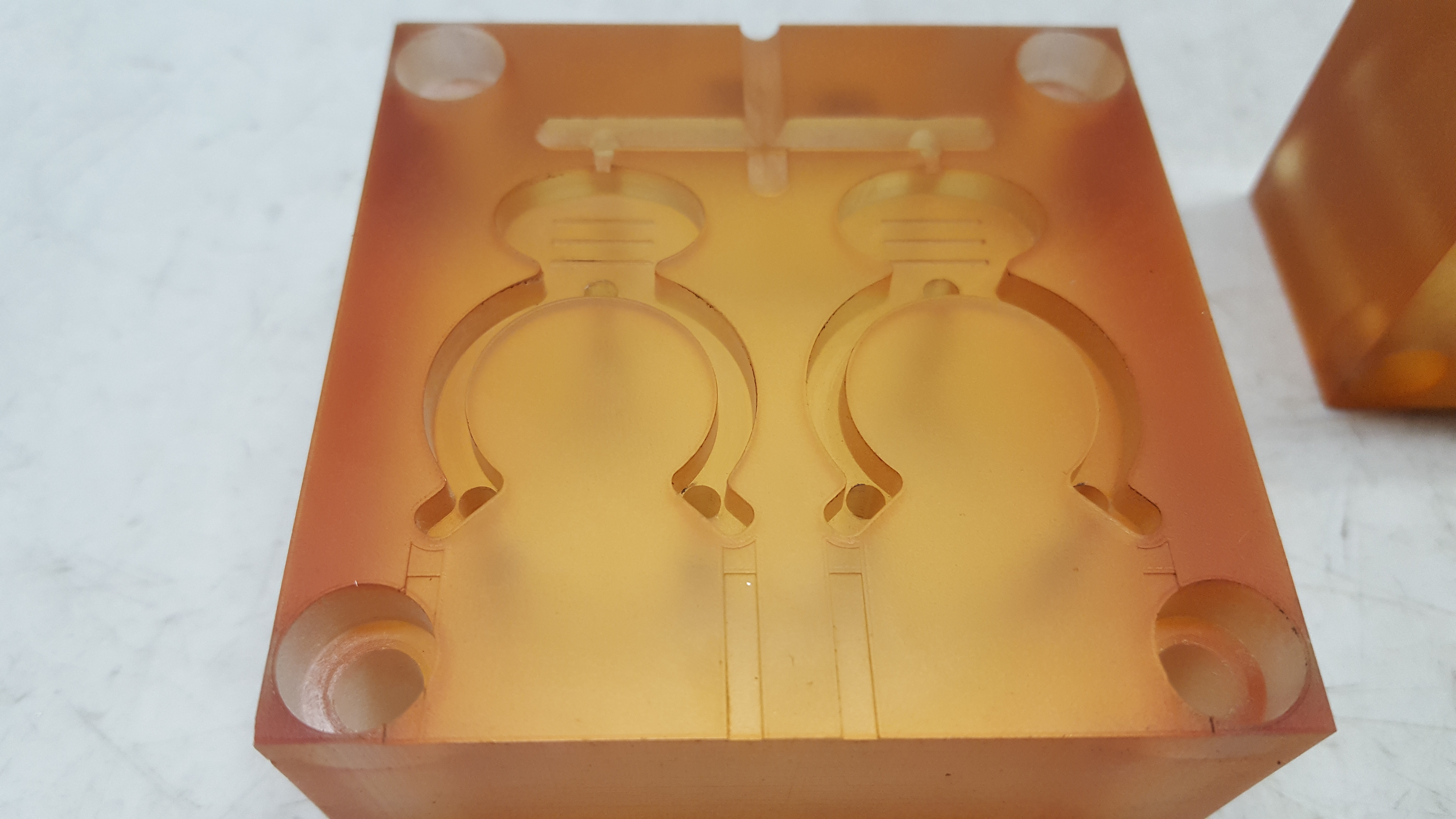

I have had great success with my first test run. 2 part clip mold

using Hylon @550F (287 C)

& got 373 shots off it before parts were unusable. I pushed it hard at the end.

Well that’s sad to hear.

Hopefully I have better luck with it.

That’s actually quite a few shots for a printed mold especially if you were pushing things a little.

I’ve used a fan to give extra mold cooling in the past. Takes forever to cool things off.

It was a good first trial. I was hoping for 10 to 50… Cooling takes up a lot of the time. I found that a 15 sec compressed air blast worked great every other shot to keep temp down but keep in mind I was pushing the temp limit of the Hi-temp resin with this material. Toward the end I was pushing 5 shots in a row with mold release every shot then cool for 30 secs. (That’s where I did a lot of the damage) I have made a air gun with a split off to blast each half of the mold at the same time to cut cooling time in half. My end thought would be to design a EOA (end of arm) to automate the cooling and spraying of the molds but this is a ways down the line. I will be running my 2nd test with much lower temps (polyp) and expect to see even more shots.

Well got my order in today of 3dresyns high deflection temperature resin. Very disappointed that the resin came in like sand and is unusable.

@fantasy2 I’m having an issue with your cartridge module. I sent you an email and PM a week ago, is there a better contact for you?

I’ve been using DigitalForge3d resin. I’ve printed maybe half a liter and it’s great. Not a single issue with prints and the price is awesome. So far I’ve been using it in closed mode by pouring it into an empty cartridge. I have not tried it in open mode, but hopefully when I get @fantasy2’s cartridge module working, I won’t ever have to. I’ll post some pics of my next print batch.

Oh wow, it completely dried up?!

Nice to hear! Very cheap resin indeed. I’ve sent you an email, please check it.

Hi Dave

I have just read your post in the Formlabs forum. I am disappointed because you wrote a negative post without giving us any chance nor time to answer your email from yesterday 18/10/2018. We received your email yesterday at 8 pm European time. I am answering now in the morning…

You wrote a complaint in the forum at the same time as you sent us an email, not giving us any chance of explaining how the product has to be handled.

3Dresyn HDT1 is a liquid which tends to solidify naturally after one day or so. This is due to its intrinsic chemical nature. It has a incredibly high Tg. It tends to crystallise naturally before polymerisation. This process is 100% reversible since the material has not polymerised nor become solid and unusable.

It is 100% usable and ready to print. It just needs a gentle warming in the microwave or in a water bath to become liquid again. Once liquid has low viscosity and it is incredibly rigid even at very high temperature.

Best regards

John M.

3Dresyns

My apologizes but this should be something you tell a customer or at least give a heads up on the bottle If it starts to solidify after 1 day! and if there is a process that needs to happen before it is usable then this to should be on the bottle so reviews like this doesn’t happen. ( I see you added a note on your website or maybe I missed it ) A gentle warming in a microwave? Do you any perimeters for reheating in the microwave? I don’t want to degrade it by over heating. If this sits in my tray for more then a day is it going to solidify in my tray during storage? I can’t microwave the tray as theirs metal in it & in open mode the tray will not heat. I must say I am discouraged at the lack of up front info. I have heard a lot of good things about 3dresyns. I will think about if i even want to try using this resin now as I don’t want to risk ruining it before i get to even print with it as it is a pricey resin. I will wait for your reply.

Hi Dave

I accept your apologies. Next time, please wait for our reply before writing a negative post.

As corrective action, to avoid this happens again with another customer we will add a note on the label saying: “warm it gently until melting before using” or we will send an email to the customer with detailed usage instructions, besides the technical information already published in our website www.3dresyns.com and specifically in https://www.3dresyns.com/pages/3dresyn-hdt1

3Dresyn HDT1 has to be warmed up gently in a microwave or even better in a water bath at around 60C until the solid melts and becomes liquid. If you choose to melt in the microwave (put the tap to the bottle to avoid the light of the microwave starts the photopolymerization reaction) please do it gently in steps of 30-45 seconds and shake it, then repeat the process until full melting of the product. After printing, transfer the resin left in the resin tank back to the original bottle. The material will not degrade if it is heated at 60C. Be careful with exposing it to room light since it will react with light as any SLA DLP 3D resin.

I would like to encourage you test it and value its extremely high deflection temperature (rigidity) at room and even very high temperature. Once polymerised in the printer, its softening point and deflection temperature is around 290C, just below 300C.

Remember to print it in open mode in Formlabs clear version 2 settings. All our standard resins have been fine tuned to these settings.

For more detailed instructions we can communicate privately by email or by phone. Please use this contact email as contact: info@3dresyns.com

Greetings

John M.

3Dresyns

Hi!

I would like to ask, if someone has succeeded with UV Photocentric Hard Cear resin ?

My Form 1+ printer flawlessly the Maker’s Muse Snowflake Latt in 0.1mm layer height and Clear V4 settings, but I wanted to print with lower layer height and I cannot succeed… (tryed Grey V4 and Clear V4 again)

I’m looking forward to response

Thank you

Lukas

Your form 1+ allows you to change a lot of parameters so I would try to play with that instead of the standard profiles.

@fantasy2 you mean to experiment with OpenFL ?

Here are pictures of my issue with 0.050 layer height. It had to be pen from Formlabs Pinshape.

You guys should really relax a bit. Forums are there for just that, now that this issue has been posted there is a record and information regarding this issue, which is useful because you obviously didn’t care to warn the consumers that this would happen.

Encouraging consumers to keep questions private only helps in raising the public’s suspicions…

Has anyone successfully printed the new FL Castable Wax on the F1+ ?

Hello, I am curious…did you manage to use the detax resin?

Did anyone try using Accura (3d systems) resins on From printers ?

I heard it has slightly different wavelength and they need vat heater. I wonder if it still worked for someone ?

Or maybe someone modified printer to use it