Final Conclusion -----------------------

So here is what I figure happened after one of the support reps mentioned something yesterday, which clicked something in my head.

To recap I could never print Nylon 12 GF below 70% successfully on our original Fuse 1 without surface armor curling. After complaining about that for weeks one support rep told me to try up’ing my chamber temperature setting. Another support rep in the same email thread, said that the chamber setting does not actually work or adjust anything in the Fuse. (As said before, a big issue is the multiple support reps jumping in and out of these support tickets, each with their own conflicting thoughts and ideas. Also after months of dealing with this, not a single live phone call was made even though this system was sold with “on scene support if the machine goes down”)

I also find the fact that the chamber temp calibration setting never actually worked on this SLS system, kind of funny, especially with the importance of it discussed by CarLayer above…

Regardless, a custom PreForm Beta was produced for me to try which 100% fixed the surface armor curling issues. No idea what this Beta did exactly but it allowed me to go down to the 50% refresh rate as advertised on Nylon 12 GF.

With that combo we were ripping out dozens of successful chambers…very happy!

Come December we saw the New PreForm and Fuse 1 firmware updates and I asked support if any of my custom Beta settings were rolled into this new release? They said “no”. I asked if I should update? They said that I "should probably keep running my Custom PreForm Beta but it is fine to update the Fuse 1 firmware. I saw that one of the updates for the Fuse 1 was in fixing the chamber temp calibration to make it actually work. So at this point I knew which of the support reps were correct…and those reps confirmed it again and told me how sensitive it is and “just little chamber adjustments…can majorly effect the prints”. Your range in adjustments only being + or - 5c

As soon as I did that, everything went to hell. Parts all seriously warping and the same batches we were running for months came out as solid bricks

After a few of those we decided to try to update our PreForm and try them together.

We imediatly tried the new XY dimensional calibration released with this update and got this warped top service.

We tried more runs on our parts, making sure the new working chamber temp was defaulted to ZERO offset and the surface armor was literally still locked onto the parts. The parts we could get cleaned out were warped. We could tell the surface armor in the Fuse camera was a lot darker looking then normal. We brought this up to support and they said it looked normal.

We looked up at the heater bulbs and realized they were burnt BLACK…

They sent us new bulbs and tried those.

We also had 3 different IR heat sensors we swapped and tried during all this but I knew this was not the issue as the Fuse overall temps were all normal. I knew that it was the Chamber bed that had to be getting way to hot as the layers would go down fine but once it switched from “PreHeating” to “Printing” the surface started to crack and crumble.

At this point after a lot of pressing… and the not so good experience we had on this system from the get go… Formlabs allowed us to do a return on the original system (which I appreciate…even though there was some more headache caused from that process with their billing department…) We paid the big chunk extra for a Fuse 1+ to show up this week.

Hoping we would start ripping out parts in record time…we saw the same pattern of issues we had on the original Fuse.

So looking up at my last post we now knew this was either

- Both chambers we had went bad at same time…both having the same issues

- Bad firmware in that the new Chamber Temp calibration feature was not working well with Nylon 12 GF

- Or we happen to get 2-3 cases of bad powder (We tested them fresh out of the jug at 100% refresh as well as 70% refreshed)

So sending this all to support with multiple folks jumping in… finally yesterday one of them said something that clicked!

He asked how the fiber gaskets looked on the chamber due to the cracking were now seeing along the sides of chamber. Soon as he said that I did note, that through all this I saw very small amounts of powder coming out the bottom of the chambers I never thought I noticed before. I also took note, that after the firmware update and all these issues that the chambers them self felt “sloppier” in the Fuse. Looking at the fiber and rubber gaskets they looked okay. I even pulled the bottom grate off them and looked from the underside.

However, when he said this, it did make sense at least with the cracking along the edges on preheating/initial printing. (Did not explain the hard surface and crumbling…we will get to that…)

SO I realized that our rubber Chamber seals lost some “loft” and not as springy. This happened all at once during just a few failed jobs obviously from the excessive heat. These chambers have only been run a dozen or two times since new.

I also pulled the bed and fiber gaskets out of the chamber. Even though they looked solid from the outside… I realized that they were "extra crispy with powder literally “sintered” against the chamber walls.

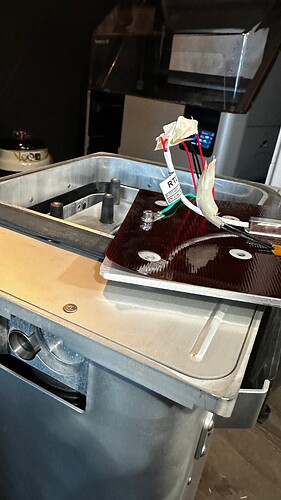

Now keep in mind, during all these issues where I knew the new Fuse firmware update conflicted with the Beta PreForm they had me running, this thing was getting HOT inside to cause all the damage we were seeing. In just a single print one of these chambers went from being the black color shown to the bright red color you see in this pic.

They said its normal to get red over time but I knew that was not normal happening in a single job…

So they shipped me new fiber and rubber gaskets because we knew that they obviously got cooked as well. As we wait for those, I decided to try and nylon brush out the fiber gaskets. While they do look better, they are definitely still “crispy” under the fuzz but I believed I could do a test with them like this.

HOWEVER… I knew this wasn’t the complete issue but only part of it. While I believed some material may have been slipping though both the rubber top seal and the fiber gasket, there was obviously still a heating issue in the bed.

So when I flipped the beds over this is what I found…both heating pads were delaminating from all corners.

So as CarLayers pointed out above and Formlabs mentioned, with bed temperature adjustments being very sensitive to get dialed in, obviously the heating pads hanging off the actual bed were most likely causing the rest of the issues. I assume these originally delaminated from all the excess heat added to the system from the firmware issues. Now, I am sure they are still the cause of the heat spikes and failed bed cracking in this new Fuse 1. So everything compiled into this total nightmare.

Because I found this, again Formlabs support has been very willing to ship replacements and are now suggesting replacing these chambers as well and not just the gaskets…

I did decide to grab my Kapton tape and was able to secure it temporally on the edges of one chamber. After doing so I ran another test job last night and while there was some slight crumbling from the bad gaskets… the job did miraculously complete with no over heating it appears in the chamber. I have yet to post process these parts…so fingers crossed but at least hopeful. .

UPDATE: after that first and only successful job on the new printer, the next few failed from what appears to be the faulty rubber chamber seals. We will see how it goes whenever the new seals and/or chambers get here. However looking at the replacements…Formlabs is not planning on shipping them out for another week…

Regardless, Kapton tape ain’t going to cut it long term as I could only grab a small edge with it but a good test till the new chambers arrive.

Final thoughts-----

If I did not personally run a business where I bug hunt issues in my own software with a solid understanding in patterning these issues to eliminate all variables…so that I can then express these patterns and issues to my developers… this entire experience would have been made A LOT worse for anyone out there expecting to get a “Turnkey system with FULL ON SCENE support if and when needed”…as that has never happened.

I do appreciate the responsiveness of the Formlabs support team and willingness to make this right, but I’d expect as we would for our CNC machines, that whenever something goes down, a rep would be there to get it back up and running immediately without all this troubleshooting needed by the business owner themselves.

Time is money…and we’ve lost thousands a day over the past few months trying to figure all this out on our own.

SLS is great and I believe this system itself is the best option for folks like me prior to stepping up to industrial SLS or even MJF…but Formlabs needs to tighten up their response and support system.

I have questioned myself during all this, if it would not have been better to go with a system through a local additive manufacturing dealer that might actually show up on scene or at least be willing to troubleshoot live if not over a zoom call but at least a voice call.

Will keep you posted. Our hopes is that everything I posted and complained about on this forum so far, was due to a total dud and 'lemon" of a first system… and that this one actually performs. If it does I will be happy to post our progress and how it is being utilized.

Have a good weekend and thanks for listening