Just wondering if the Form 3L with its increased build volume will see a new Form Wash, and possibly Cure, station that will accommodate larger prints. I would love to see updates to the wash and cure platforms even if only for industrial use. We have a Maker’s Hub where I work and they are always acquiring new products for prototyping and larger prints is always desired. The Form Wash has made cleaning a breeze but I wonder what kind of hassle the 3L will be when cleaning something that large. Leave your thoughts below.

Hey @Charmande!

That’s a terrific question! While there likely won’t be a full Wash/Cure system for the 3L at launch, I can confirm that we are working on an equivalent solution for the larger machine.

Before that system is available though, we’ll make sure every 3L comes with some way to wash parts. More details to come!

Thanks, that’s good to hear can’t wait to see these products. I’m sure even some other companies who do not have the 3L and just a few Form 2’s or 3’s would love this as they could batch clean items as they come off multiple machines.

That’s gonna be the size of a dishwasher!

Hi! I’m one of the engineers working on that larger system! Glad to hear your Form Wash has been working well for you. I agree that using a larger wash to clean multiple Form 2 / Form 3 parts at the same time is also a nice benefit.

Dishwashers come in all sizes and shapes, but yes of course this product will need to be a bit bigger, since it must wash parts 5x the size of Form 2 parts

Of course, because this is R&D, I cannot share much in the way of product details or timeline, but I’m writing just to emphasize that, yes, this is something we see as important that we’re working on actively. I’m looking forward to delivering a solution!

I wonder if it might work as well to use some kind of spray system rather than full submersion soaking, since that’ll be a lot of IPA to soak things for the larger prints.

Good idea @Zachary_Brackin,

Me personally using a squeeze bottle with small nozzle to wash the large parts that i’m printing in Formlabs 2. I’m washing it to a bin while still connected to the build platform and it is extending the life of the washing tanks.

If this kind of washing will be done automatically for the 3L, it will save lot’s of IPA, especially if it will be applied by pressure, the remove of the liquid resin from the parts will be much easier!

Keep up the good work Formlabs Team!

Yeah, not sure I want to be buying IPA by the 55gal drum!

I’ve tried a few things and the IPA works best for me.

That resinaway is the thing I’d use last, if at all. Other things people have suggested did not work any better than IPA and all of them present disposal issues equal or greater than IPA.

Hell, I’m tempted to try a cheap but high octane Vodka!

Any solution, pun intended, for washing a print that large is going to come with its own inconveniences BUT having prints that big will wash that inconvenience away. Pun intended.

For me ResinAway is working great on all resins… except Formlabs one! Then I’m 90% resinaway + 10% IPA with some printers and 100% IPA for the Form2 prints

I’m using resinaway on Form2 resin (grey and clear v4) in the ultrasonic cleaner and it works great. Only thing bugging me is that awful “roses” smell but RA is not flammable which is a great safety plus. After two washes of 7 min in ultrasonic I rinse it under running water and then finish curing in the FormCure. Haven’t had any problems and parts don’t warp nearly as much as after washes in IPA.

I think I’ll need to find an ultrasonic cleaner which can fit Form2 max print volume size… Thank you for the info, weird that i had so bad results.

About other brands, I’m using the RA, then after rinsing with tap water, I spray some IPA as tap water is whitening the resin most of the time.

Forgot to mention it… after washing the part with water I dip it in IPA for a few seconds just to get water off since otherwise it will take forever to dry the part before curing.

Try DPM(dipropylene glycol) or the by Formlabs recommended TPM(tripropylene). It doesn’t smell at all. ResinAway has an additive which lowers evaporation but smells strongly.

The pure stuff is cheaper as well!

[quote=“Boris_Krzic, post:13, topic:24077, full:true”]

Forgot to mention it… after washing the part with water I dip it in IPA for a few seconds just to get water off since otherwise it will take forever to dry the part before curing.

[/quote]Better have water on the part than IPA… After DPM bath we have them rinsed in warm water and then blow off excess DPM/water and then straight in the cure.

I only tried resinaway on clear prints to see if it would reduce fogging.

It doesn’t.

So it’s useless for me.

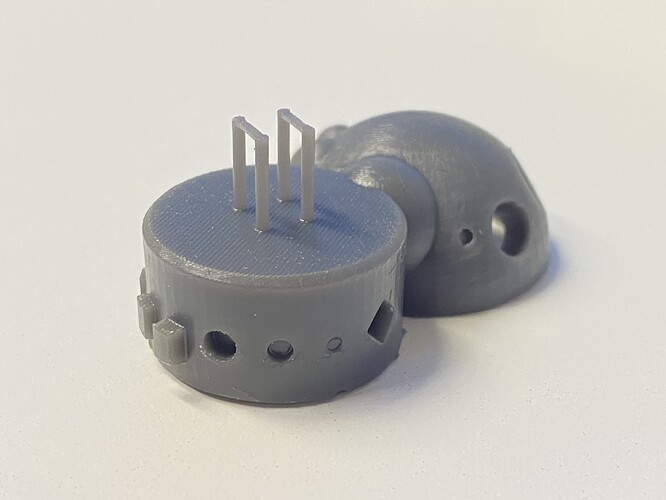

Really looking forward to a proper solution… this is what comes with the 3L:

It looks like an updated version is coming down the pipe.

Are there any new ones in the wild? I have to decide if I’m going to save this one to give to my wife for Christmas for cooking chickens. ![]()

Hi horton- I am very curious to hear how you are doing with the 3L. There isn’t much info on the forum about the new larger machines that I can find. I am especially interested in hearing how that large resin tank performs with large prints. I’m kind of surprised they illustrate a different wash tank than what they sent you!

It took FOREVER to fill up with resin lol, even with two cartridges installed. I didn’t think I should just pour resin into the tank directly, because that would alter what the system thinks it’s used. Maybe it doesn’t matter though…

I haven’t printed something large enough to warrant a wash in the chafing dish yet, and I’m not really looking forward to the process.

I saw in one of the videos or maybe it was one of the webinars that someone poured the first liter straight into the tank and then put two full ones in the dock. Maybe it wasn’t the full container into the tank but it seemed that it was the fast way and not harmful. Do your prints look good compared with your previous form3 machines? Does the flexible tank floor seem substantial to you? And finally, how long was your wait and what was delivery like? Thanks for answering questions- I ordered one of these and the way my form3 is working as compared to my form2s, I’m getting a little nervous. Reading tons of negative posts isn’t really useful- I’m way beyond my early love/hate thing with FL and my experience is that it’s not all the hype promises but it’s still great and useful.

This is the Treatstock test piece I just did. Tough 2000 at 100 micron.

I feel high print quality has a lot to do with orientation and keeping the mirrors/glass/tank bottom clean. Spending the time on orientation will save post process time.

I have three Form 2 machines, so this is my first 3 series. The sound of the LPU pushing up against the bottom of the tank the first time was a little concerning - it sounded like it was about to pop through lol.

Looking forward to getting some jobs going through on it!