Hello Formlabs Community.

I know it’s an exciting time now that the Form 3 is finally here. I saw the first impressions review here. @Mark_Harrison covered the printer very well here. As he mentioned, “The “film” is very thick and nothing like what we have seen on some other low cost machines. It is wrapped around metal rods on each end to hold it in tension and there is a secondary seal on the interior or the tank. Only time will tell, but initial impressions are very encouraging!” I am thinking of getting the big brother, the Form 3L. I am trying to scour the internet for reviews and people’s comments to make an informed decision. It’s strange why they would not send out test printers so people can review them and they can have feedback to resolve the minor bugs/issues.

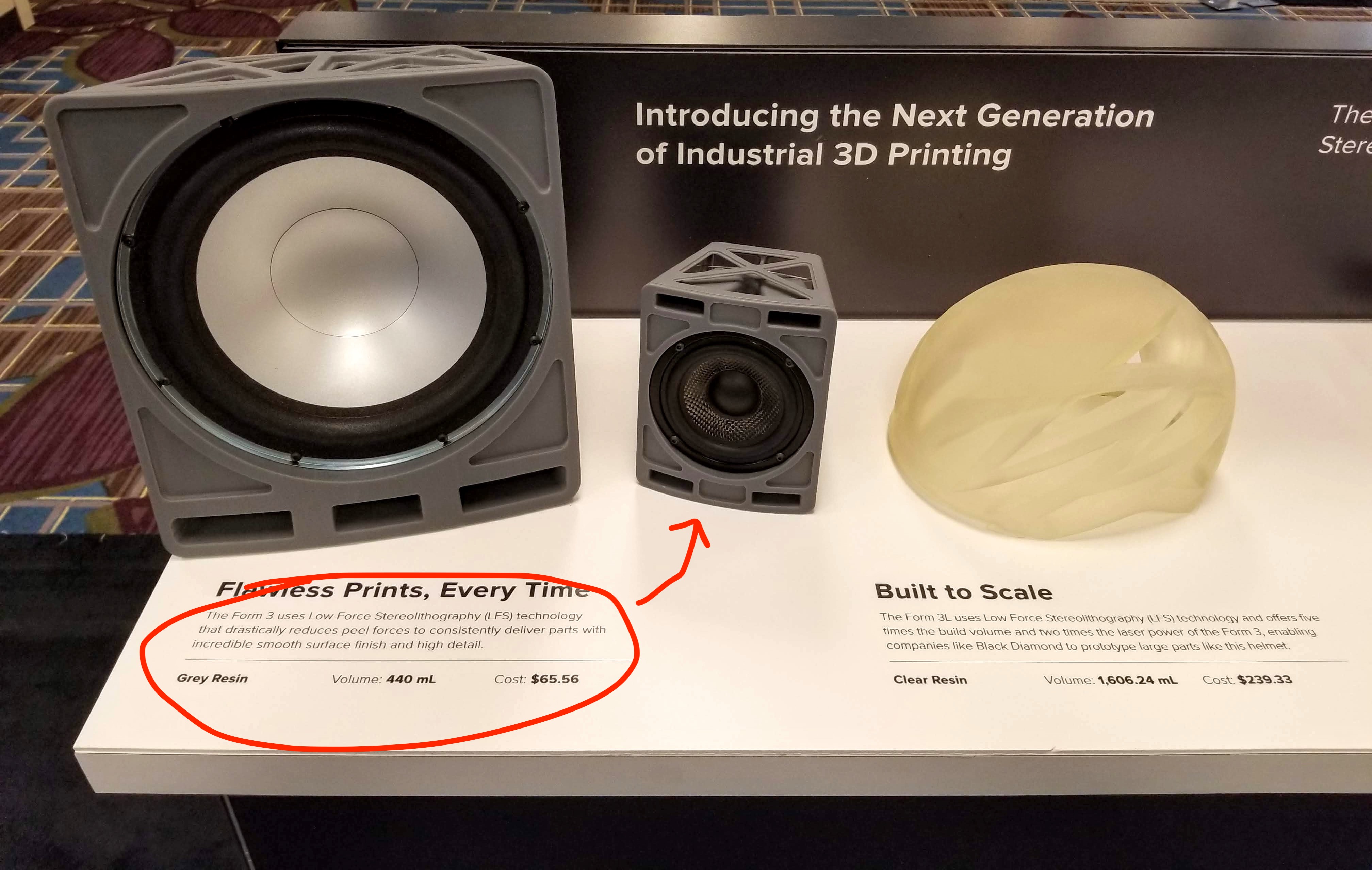

Now, coming to the main issue. I FOUND THAT THE PROMOTIONAL VIDEO FORMLABS RELEASED FOR FORM 3L HAS A MAJOR MAJOR ISSUE. THE PRINTED PART SHOWN IN THE VIDEO (A SPEAKER HOUSING), IS BASICALLY A FAILED PRINT. They added A FAILED PRINT for the video. Look at the series of images below and you’ll understand why. @Formlabs I hope you’re reading this. @Mark_Harrison your post is very popular and I hope you can help spread the word.

The first image we have here is the STL file loaded in the Preform software. Make note of the top section of this STL. Just make note of how it looks and how it should form. We will come back to this.

The second image is of the printer UI, where it shows the part in a preview window once the part is finished. Note that it’s basically what we saw on Preform. Still everything is okay. Follow the top section.

Now we come to the main stuff. I don’t believe it that no one else noticed this. Take a look at the image below. Notice something off on the top section? (circled). THE PART DID NOT FORM! IT IS A FAILED PRINT ON THAT SECTION. It has multiple final layers just missing. It should be symmetrical. The edge did not form at all. Look how close it is to the opening and compare it to the section near the build plate.

Here is another picture showing it more clearly. Compare the top section (red) with the bottom section (green). You can clearly see that it just did not print by approximately 1cm. The side edge of the speaker just did not print on the top section. See how the edge on the top is literally connected to the circular opening, and on the bottom, which formed correctly, it has an offset!

The final image. This is where all my speculation came true unfortunately. A small speaker, which has been printed perfectly, is placed side by side with the same big speaker. Look how symmetrical it is vertically. The large speaker is not the same. See how cleverly @Formlabs tried to hide it by darkening the area on the left? I must say commendable try since many people didn’t notice at. I might be some of the very very few who did. I did not see anyone notice it in the youtube comment section either.

Please don’t misinterpret this post as hate. I love @Formlabs and their machines. I am as excited as the whole 3D printing community. But this worries me. Why did they release a video like this? This shows that their Form 3 line is still not fully engineered - mainly the flexible resin tank. The new LFS technology with the new tank is what might have caused the error on the Form 3L. Maybe marketing forced them to release the video without even solving all the issues. I am sure they knew their part failed. It’s unfortunate that they chose to go with it. It shows that they did not have time to solve it. Is that a reason why all their orders are delayed? Instead of apologizing for delaying orders, why don’t they take time to fully engineer the machine, and then release a video or put it up for sale when they are ready? All this haste is doing no good.

All I want to know now from @Formlabs is what happened to the part? Why did the Form 3L fail like that? Have you resolved that issue? Is the LFS fully capable and tested? What is the life of the resin tank?

This issue makes my trust in Formlabs waver. Before I saw this in the video, I was 100% sure to order the machine within a couple of days, since I want to get my hands on one as soon as possible (knowing the delayed orders). Now, it seems like a big risk. The community needs to know this. Whoever is reading this, please help spread the word. Make people aware. Make @Formlabs aware. How can we place pre-orders for machines that haven’t even been reviewed, especially after looking at this video, that @Formlabs themselves posted despite knowing the print failed. I am glad I noticed this. Hopefully it helps the community.

Here is the link to the video if you want to see it yourself.

Thank you. I hope this post sees the light of the day.

@Frew @Zachary_Brackin @JohnHue @KenCitron @Randy_Cohen @Dudemeister @fantasy2