I got my Form 1+ with the intention to print architectural models. I have had it for a few days (maybe a week or so) since FedEx delivered with damaged packaging - as it currently is, my orange cover need to be replaces as it is cracked. I am waiting on formlabs to send me a replacement, I am sure they will come around sometime.

Despite of that and after exchanging some e-mails with them I decided that I would take a chance and test the machine.

To my surprise, its print pretty well and I am believe that many of the issues I am having at the moment have to do with the learning curve of understanding supports and the overall workflow of my application of the form 1.

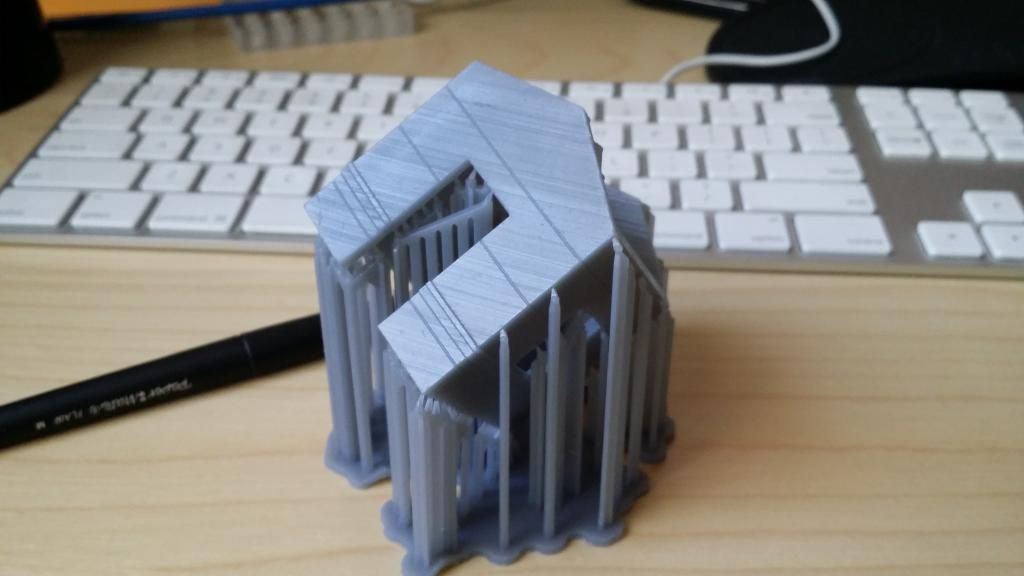

Below is my first print of an architectural model to scale.

(redo print).

I attempted to print a model of walls, a door and a roof at 1/8" = 1’

I set the “parts” in preform and let the software do the positioning of the models and the generation of support.

I run the print at 0.050 m, in an attempt to a nice crisp model and really see what this machine can do.

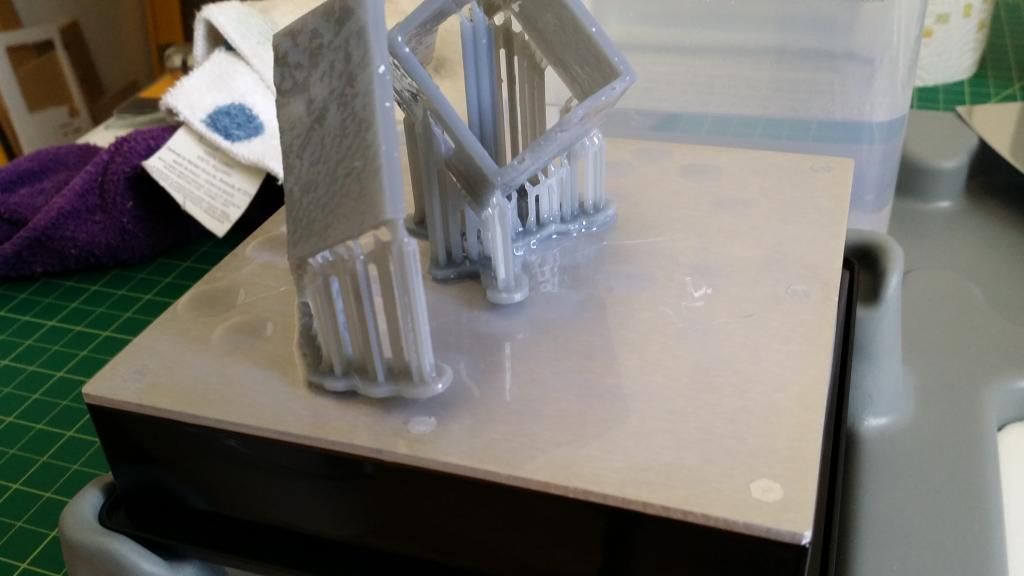

When the print job finished and I removed the platform, I noticed that the door model had not printed, and the base of the other two models had lifted. I am unsure as to what caused this (more on that).

Foreground: rood , background: walls, right: missing door.

There are also several blowouts and surface imperfections. I am not sure if those are related to the physical size of the printed parts and resolution. Meaning the object is just too small?

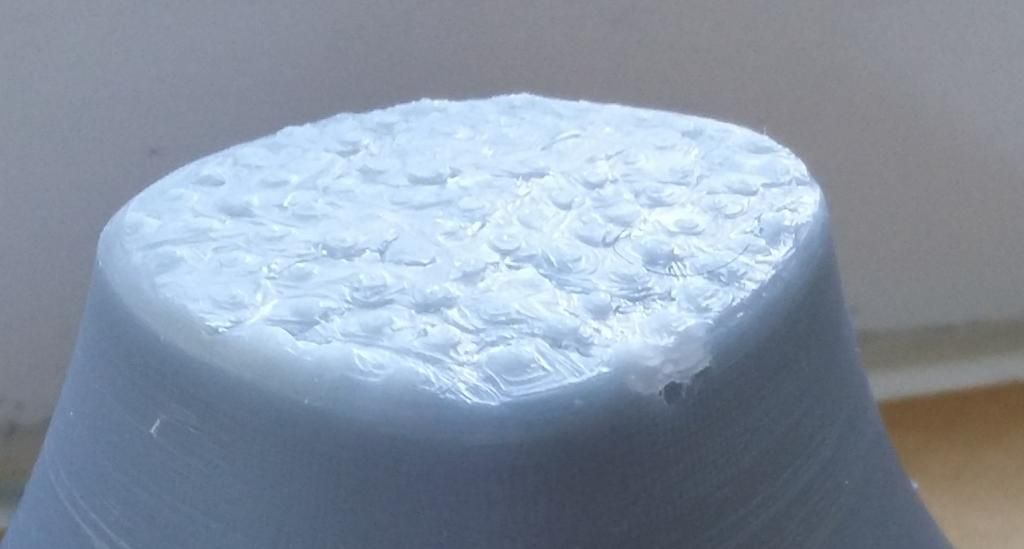

See below for the imperfections:

There is the underside of the roof.

The overall geomety is pretty good (not skewed) but the the planes on the inner (top most side when printed) is deformed.

Here is a print of the walls:

The same deformation occurs on the gable end wall which is the top most plane when printed.

This is consistent with the errors of the roof and some minor surface error my second attempt of the part (more on that)

REDO at 0.1 and Larger scale.

From reading other users threads I realized that placing supports manually is an essential step of the workflow (hope formlabs is listening to our suggestions in improving this). So I decided to print the walls models again. This time I scaled a little larger (twice the size of the original) and printed again.

I changed the resolution. I went to 0.10 (original printed at 0.05) and took the time tom add several supports manually.

I did not change settings for the support base thickness.

To my surprise the print came out very well. Much better than when printed at finer resolution. Since I changed more than one element in the workflow, I can’t say for sure what helped. I am going to say that the manually added support did it.

Front facade:

Side:

Manually added supports, internal and external.

I believe this helped the most.

The print stayed on the platform all night and I was able to easily remove it by identifying an using the created “quick release” tabs on the base.

One things that is consistent between the original print and this new one is the imperfection on the planes that are facing up as the machine prints. If you take a look at the image below, you will see small marks as if blowout wanted to start?

I am not sure how to counter this and I wonder if it has to do with the type of resin (grey) or model orientation (mind you the software oriented it this way),

I am please so far with THIS print - although not at the right scale which is important. However I am impressed with the printers ability to produce the detail (again unfortunately no at the scale I wanted) the score lines on the elevations as well as the double step banding around the banding are all there.

I few things I want point out is that I did not top off the resin tank for this print and I am using formlabs resin.

I may print this model again at 0.05 to have an apples to apples comparison and post again.