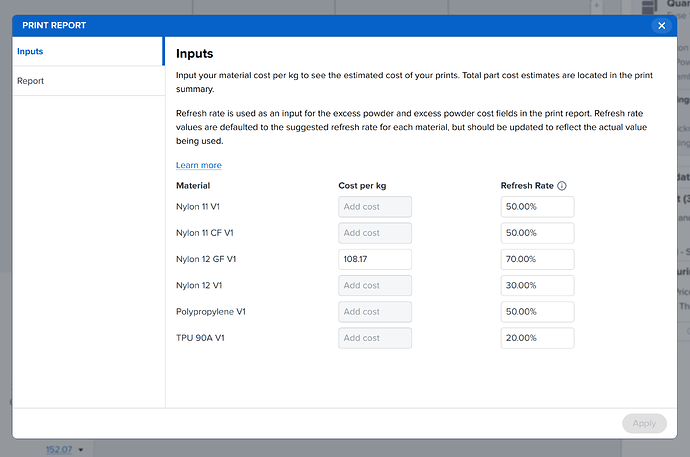

While I like seeing how much my parts will cost within PreForm, as far as material costs… it is a bit off.

It has been proven that Nylon 12 GF must be printed at a 70% refresh rate to produce durable parts that are not brittle and just to keep the print job from failing repeatably.

So when needing to run 70% refresh, you are going to be throwing ALOT of Sifted powder in the trash to empty the Sift as your Refresh rates are “upside down” at that point.

At one point a Formlabs rep tried to tell me to “save all that powder”… but storing excess powder that you can never use… did not make sense.

Anyway, here is the issue with the new Report in this example.

With 70% refresh and the cost added…

So as you can see it looks great up front… with this 3 component part estimated at only $31.50 and the three components costing each $25.47, $3.77 and $2.26 up at the top… but that obviously is not the correct projected cost per part.

At 70% refresh you are only going to be “saving” 30% of that “excess powder cost” down there on the bottom right of this report. Even at 50%…I’d rather see each part quoted with the refresh rate in mind…

In this scenario the “Part Cost” would be well over $100 and no where near the “$31.50” estimate given.

So not sure at a glance what this report feature would provide you with…other than “wishful thinking”?

Note… making this part for over a $100 would never financially make sense over other manufacturing means…as this powder is WAY OVER PRICED to make production parts possible…but even if this part was a “prototype” or for “aerospace”, this new cost estimate is not very useful as is, at providing a quick estimate at a glance.

In this scenario, you are better off just subtracting the “unsintered powder” in your chamber by the 30% that you could actually salvage (not even all that 30% would get used in the next job with the additional refresh), adding up the total used cost of powder in that chamber and dividing that by the number of parts in that chamber…

In fact, with Nylon 12 GF, to be on the safe side, with print failures, layer shifts on larger parts and everything else with vacuuming out the trays, doser, etc before the next print…at 70% refresh and all that factored in you are better off just taking 100% of that powder used in the chamber and dividing it by the number of parts within it for you actual “cost per part” Haha sad but true…so in this example we would just go ahead and say that this assembly would cost the $152.07 you have down there in the Total Print Cost + post labor ![]()