Carlayers

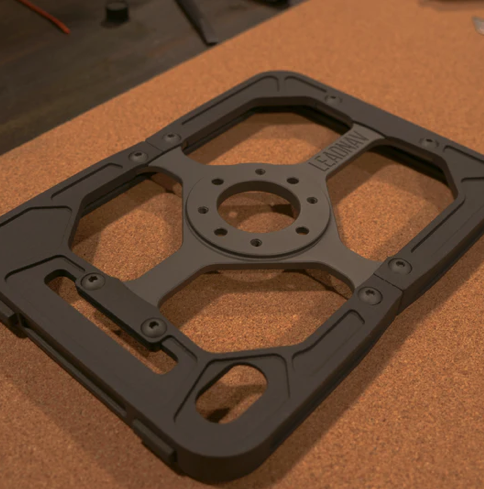

That’s where we’re kinda scratching our heads in what to do. In our own parts we deal in Offroad automotive in the desert. That combined with a race engine can some times put temps near 200 degrees. We are mostly making housing for electronics so the item itself can help maintain structure a bit even when softening but there are bolt holes in the design where you have 1mm between the bolt and brackets etc…

We also do some consistent outside contracts for thinner items to include blade/knife handles and sheaths where there are 2mm springs n thinner walls.

Honestly Nylon 12 GF has been working very well all around even though occasionally we get cracked springs on those smaller parts. However, sticking to the 70% refresh (while tossing 20%+ of our never used sifted powder in the trash) has made printing this material very consistent without failure and without it getting too brittle. If we dip below 70%, we start to get more print failures and more breaks in the parts when used.

Here’s the problem… COST.

We can’t scale this outside the premium market and direct to higher end consumers. Material cost n all that waste is insane.

So this week I dedicated to trying nylon 12 to see if it is acceptable for both use cases. However, while I too can appreciate seeing Formlabs still innovating…they couldn’t have launched these materials at a worse time to confuse the hell outta us. Haha

“Tough” sounds like it may be great for our smaller parts/outside contracts for our smaller end us knife handles n sheaths as you suggest… but for our own parts sounds like it would soften to much possibly… we were already concerned with nylon 12 being lower than GF.

Also, at what refresh we’d need to print at with Nylon 12 is still undetermined. I’ve done two 100% chambers of test parts n they seems good if not slightly better for our parts in strength…but we will see at lower refresh. I just did a 40% refresh chamber to try but even at 50% it would be half the cost of Nylon 12 GF. (Still ridiculously expensive but at least way more feasible).

The other thing I’ve found as I sit here staring back n fourth between the two… Nylon 12 feels like a toy. Lighter and lot more “plastic” feeling. Feels weaker. Whereas Nylon 12 GF feels almost like stone and more substantial. It also has more of a finished look to it with a slight sheen and less “powdery”.

On that note… did you ever invest in the Blast? Wandering how the fit n finish would compare out of that and if people are happy with it or not.

So yea…cool to see the new materials. I am leaning towards the compromise of switching down to Nylon 12 from GF strictly due to parts costing half between the two but still unsure on all the push/pull compromises between the two.