Alrighty all, I appreciate the efforts of everyone still reading this, this will probably be one of the last larg-ish updates I will make on this thread. It is about 3 months since I have met with Formlabs representatives to discuss feedback, no meaningful changes in Form 4 printing behavior and print setting profiles have been made as of end of September 2024. I did a little more printing and testing, and here are some conclusions I will draw for now.

First things first, I will pretty much completely backpedal on Precision model resin, it does not fix most problems of dimensional accurate through some more testing. It is a little better than most general purpose V5, but more like 10-20% better and not the previously though 75-90% jump in accurate. Here is what I mean:

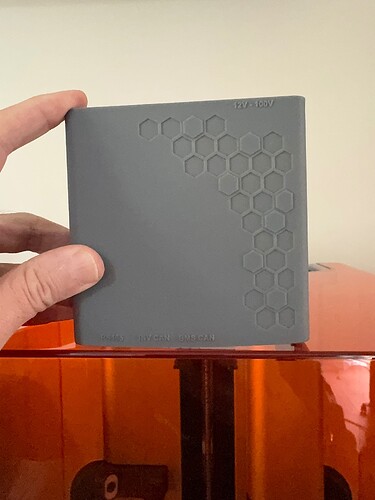

Firstly, here is a thin and square thing in precision model that the $500 FDM printers today will eat for breakfast, if you look closely you can see that in reality none of the edges are straight:

About a 2-4mm curvature away from a straight line on both axis, drew some dramatic red lines to illustrate the warping direction:

For reference, model was oriented like this:

Form 4 has so far struggled with this in every material I have used, the expanding area where the

model first attaches to the supports bends from the rest of the part. The expanding areas that are supposed to be straight instead forms a curvature that results in 2-5mm of inaccuracy over just 100-150mm. This also occurs in chunky models:

Left side of the building is lower than right from orientation.

Btw, this is all with precision model, of which exhibits by far the best stability behavior yet still does not achieve the 0.2mm or 0.15% advertised. Every other material is much worse. Furthermore, I discussed above about how presion model and general purpose material spontaneous warps over time, and here is an example of something I got mostly flat but curled itself after being in a room for just 1-2 weeks:

Also I did dip my toes into Tough 2000 and realized it has similar poor accuracy as general purpose V5, and declined a client project. See examples below, obviously this part is supposed to be square and flat:

Could not get it to print straight or cure flat despite being on supports.

So where does this leave us?

So far, my experience has showed these materials do not print the advertised accuracy:

- Grey V5 (consistent 2-5mm warping on straight edges, expanding area print issues)

- Clear V5 (by far the worst, even worse than grey v5)

- Tough 1500 (warping almost as bad as grey v5, added curing reliability issues, poor overhang and bridging performance worse than general purpose materials)

- Precision Model (slightly better than grey v5, still consistent warping across 100mm edges of 1-3mm)

- Tough 2000 (warping about as bad as precision model, added high difficulty in warping during curing).

By the way, I will add the reason I rarely print directly on platform is this:

This did came out mostly flat printed on platform, but curled dramatically during curing so much so that the model cracked from internal annealing forces. Angling on supports and curing on supports helps a lot; furthermore, a lot of geometries lead to much easier supporting on angel and I think this is a big advantage of SLA to print weird geometries.

Speaking on internal annealing forces, I do have a hypothesis of a potential cause of this warping, Form 4 flashes an entire layer at once, generating a lot of internal forces that seems to add together across many layers, pulling into the part and bending (Form 3 obviously does not do this as it scans each layer slowly and progressively so I have never really have seen this issue on Form 3). Coupled with v5 general purpose materials that are designed to print and polymerize fast, well, perhaps here we are. This might mean a long road to a true fix to this issue. But hey, I’m not an engineer and this is speculation at best and conspiracy at worst. I do think this means a long, long road of software and hardware optimization before useable reliability for me.

At the moment, I cannot live with a near 10K system that has delivered about 30% reliability of client deliverable parts. I have already begun conversations to look elsewhere. This all may change, but I do wish Formlabs best of luck with improving this system and you all to hopefully not be having too much headache.