Evening! Let’s address some of these things…

This certainly is something very specific experienced by me. For what is worth, its coming up on like 4 month since launch of Form 4 and this for all intent and purposes is a young system. I expect bugs, but a reasonably useable product (which is not the case currently for me). I do believe as time increases and more people buy these, it is inevitable that other people will encounter this as the part warping during printing is massive and a easily reproducible issue. I have already met with representatives from Formlabs, who acknowledged this being a large issue and seem to be working on it.

There is nothing mysterious about post-processing/curing hassles as well as part instability (spontaneous warping over time) either. These are old problems since days of Form 1/2. Read the forum or talk to anyone who have printed on one of these and you’ll find that. I am fortunate this is not my main business and I am not losing anything with the time and money I have spent doing this, read here or talk to anyone in AM and they will have way less objectivity and have way more choice things to say about Formlabs. I have said my opinions and my experience, and you are free to read and think what you want; I am simply passionate about additive and enjoy sharing my experience extensively so perhaps I can contribute to users and maybe Formlabs.

I was initially excited to see some flat and accurate parts, but unfortunately how you achieved these results kind of proves my point:

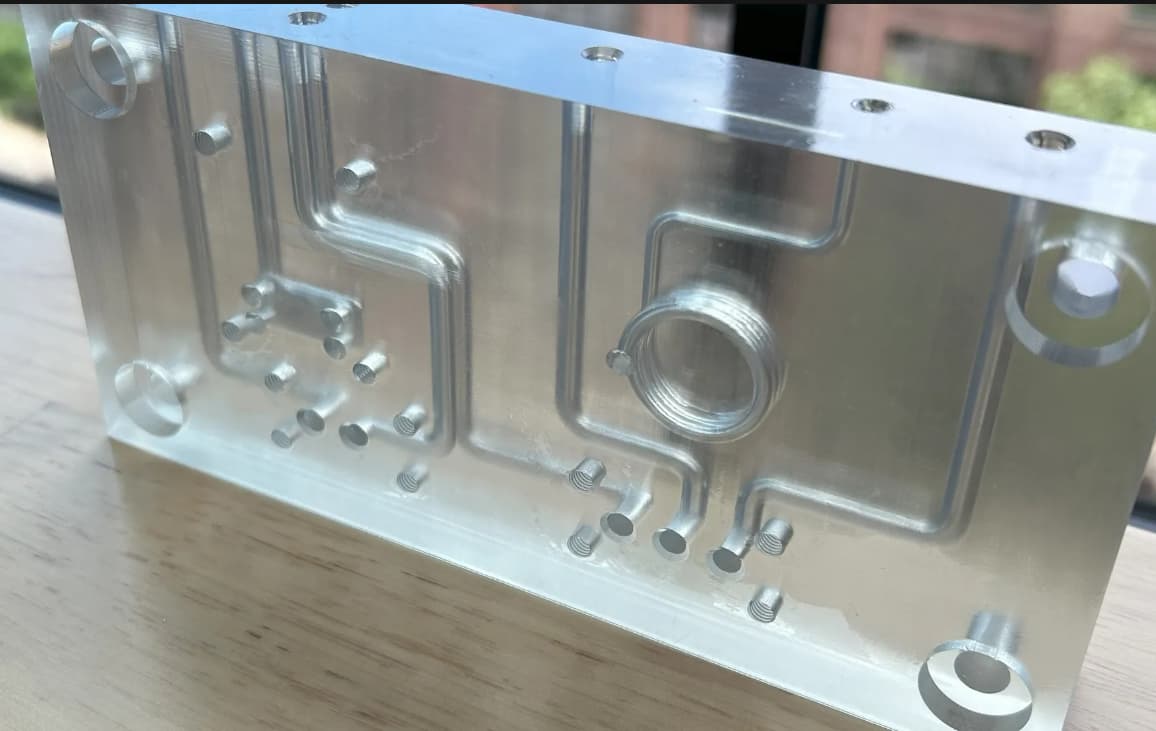

The thin manifold should be very easy to print, and I can probably count on a first print success from Form 3 if I were to make it on that that. It sounds like you had to make many iterations in order to finally get this to work. The fact that you had to go through a substantial iterative process for something that looks very simple to make and change its geometry to get this to work on the Form 4 is a huge problem. Some clients come to me with parts similar to that they have had successes manufacturing with professional service bureaus. For me to turn around and claim their parts are unmanufacturable without substantial part redesign is not a solution. I am sure one can design and only print things that print directly fit on the platform and the ideal of being “a good part to be 3D printed” and get some reasonably results but this is just really far from reality. I follow this guide (and the version for Form 4) religiously and frequently process files with Meshmixer and Materialize to adhere to this:

How to Design for 3D Printed Parts on the Form 3 | Formlabs, but at the moment the Form 4 cannot reliable achieve it’s own guidelines. Other printers including $250 ones (albeit with a lot of work and tuning and only sometimes) and $250K ones I can order parts from can easily print these guidelines and what I would want to print easily.

Again, that clear manifold looks beautiful. Unfortunately, maybe I will see 1-2 things a year that I can stick on the platform and print with no support material like that. If I tell the people I make things for they have to make only things like that they would drop me and go order parts from someone who can do it… it’s not hard.

If you took the time to actually read my “long winded ramblings” you will realize that at no point was perfection ever mentioned as a requirement. All I want is Formlab’s own marketing and design guide to be true. General purpose materials should have straight edges and no huge visible defects, and engineering resin should be reasonable enough for me to trust tolerance to install as replacement parts for my engineering clients. I don’t need or want sub-micro or like metrology level accuracy you can only tell with CMMs. Even large flat surfaces that are only mostly ok are good enough. This is a VERY VERY VERY resonable requirement and something ALL industrial 3d printers should have. Afterall, consistent parts within 0.2mm-0.3mm or 0.15% (or 0.3mm across like a 200mm part) is Formlab’s own claim:

There are various other things such as marketing guides that claim this.

If anything, Formlabs is the one advertising perfection here, these are ripped straight from the website:

Ironic that above images shows that Formlabs advertises tolerance that can match initial designs, and then you have to print and reprint and change the initial design because the printer can’t do it… But that all aside what that do phrases “unmatched reliability,” “geometry freedom,” and “parts printed in every resin will match YOUR design parameters every time” mean to you? I think people who do not have the knowledge of you or I will be sorely disappointed by the current performance of Form 4 if they really only have this surface knowledge.

Again, I understand 3D printer is not magic. I have been in this game for a while and used printers from $250-250K for professional work for more than a decade. I am not “10000 hours of printing experience” but calling me anything but an experienced user compared to who Formlabs in reality is marketing and selling this to would be not accurate nor realistic. I know what is acceptable for clients, and what other systems can do through being in additive for a while and making a lot of expensive mistakes. If extensive model processing for many models in 3D party software to adhere to Formlabs guidelines, 1-2 hours of support editing by a very experienced user, and pulling every trick in post processing still achieves questionably reliable results, some failing and entirely warping during printing, then what conclusions would you draw? If this was a $1000 open printer where I am responsible for tuning, I would have not made this post but rather be scheming ways to tune this out myself. Instead, I am reading a full webpage by Formlabs about how they make industrial 3d printers: High-Precision, Blazing Fast SLA and SLS Industrial 3D Printers | Formlabs. Anything I have demonstrated above and extensively documented with (I even have a google drive folder in my initial folder with test parts and pictures) with having warping or bad issues are usually just thingiverse or printables.com models edited. If I printed them on true 3D systems or stratasys polyjet 3d printers (that Formlabs used to have webpages about how they can outprint those machines) they will work near flawlessly. This should be super easy and realistic to do, and Form 4 should eat these for breakfast. Again, if I can get like 95% reliability on like a few good materials that’s all I want (bare minimum of a $10K system marketing itself to be a turn-key industrial solution). Instead, I am here writing up novels for Formlabs to document and hopefully correct these issues.

You are right in these marketing statements being “nominal claims:”

Indeed, these accuracy claims are nominal sense that they are in name only and are not substantive or real currently… They are not currently achievable with:

- Using 3D party software to add/ correct unprintable geometries according to Formlabs guidelines.

- Supporting and orienting with many MANY trials by a very experienced user.

- Extensive and nuanced processing by a very experienced user using new equipment, fresh solvent, and many, many tricks.

This has turned into a many months long journey with many frustrations, but I will say this as an absolutely undeniable fact that is perhaps more important than anything I have said here. Formlabs service from sales to support to anyone I have interacted with was forever the OPPOSITE end of the scale compared to accusing their users of “long winded ramblings” and assuming their users are not capable of using their machines and always misdesigning features or improperly using their software. They have been nothing less than exceptional. Just scroll up in this thread and see Formlabs product leads and even executives responding to me in person, scheduling meetings to hear my feedback, and taking quite frankly brutal criticism IN STRIDE and on public forum. Not an ouce of blame cast, nothing was dismissed, and nothing less than listening to all of my most trivial concerns was done. I can say this about ZERO other 3D printer companies, additive service bureaus, or resellers I have worked with. This deserves absolute commendation and I am convinced with this attitude problems like with Form 4 can be solved. This is the reason I have kept this system and am even in the process of possibly shopping for a Fuse. I admire this company and want to support it.