Since I was tired of constantly having to replace the plastic vats, I decided to try a different approach. I had a guy build me an all-glass tank out of borosilicate (Pyrex) glass, and coated it myself with Sylgard rubber. So far, it’s working great. One thing I’ve noticed is that after 4 successful prints, I don’t have the usual buildup of semi-cured floating resin globs that plagued my earlier attempts. I wonder if the plastic window scattered the light more, causing those things to form, which impede printing, stick to prints, and constantly have to be filtered out.

Andrew Werby

www.computersculpture.com

3 Likes

It’s possible. I never got any boogers/floaters on my other (DIY) printer with a glass tank.

Be careful when handling it, though - i cracked one (pyrex as well) just by bumping into a door while carrying it.

Cool, can you upload pics and or plans for your tank? I too was looking into making tanks myself (but out of plex), once the weather got better, as my tablesaw needs to be run out of doors. How did your fabricator handle the spherical dimples for the ball-springs to index into? Also, can you share the fabricator you used?

-C

Sure; this is the only picture I’ve taken of it so far. The trouble with Plexiglas (aka acrylic, the same thing the regular tanks are made from) is that it degrades if washed with isopropyl alcohol, so you can’t clean out the resin, and it’s nearly impossible to clean the window if you get a fingerprint or any gunk on it. So it seemed that glass was a better choice. It also adheres better to the silicone coating, so it doesn’t have that annoying tendency to peel away.

Sure; this is the only picture I’ve taken of it so far. The trouble with Plexiglas (aka acrylic, the same thing the regular tanks are made from) is that it degrades if washed with isopropyl alcohol, so you can’t clean out the resin, and it’s nearly impossible to clean the window if you get a fingerprint or any gunk on it. So it seemed that glass was a better choice. It also adheres better to the silicone coating, so it doesn’t have that annoying tendency to peel away.

I didn’t do the spherical detents in this one, although it wouldn’t be too hard to grind them in. But I had a problem with the standard tank recently where the spring-pins got stuck and wouldn’t let go, which meant I had to pry the tank out semi-destructively, and had to send my unit back. So far, it seems to work fine without them.

I’ll have to ask my fabricator if he wants to be shared here - if so I’ll post back with his information. I probably should also clear this with the Formlabs guys so they don’t sue him or anything for doing this - is anyone from Formlabs out there listening? Is it okay to build some aftermarket tanks out of glass and sell them?

Andrew Werby

2 Likes

thanks, looks great! can you share what it cost you to have this made? maybe you can work a gig with FL and have them sell them as an upgrade

just thought of this: is the whole thing glass, or just the bottom?

In this version, the whole thing is glass. There might be something to be said for using some kind of alcohol-proof plastic for parts of it, but for simplicity’s sake we decided on all-glass for this one, just to see if it would work.

I paid $100 for this one. If the fabricator gets multiple orders, he might realize some economy of scale, but the glass itself is pretty expensive, so it probably will never be as cheap as the “consumable” vats.

Andrew Werby

www.computersculpture.com

Isn’t the problem with the PDMS that gets foggy – not the vat itself? It seems that you would still be replacing the pdms just as often.

Do you think the glass tray has a higher level of optical clarity compared to the plastic used by FormLabs?

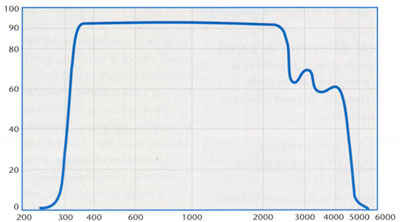

Using regular glass on the bottom is a bad idea. Glass blocks UV light on some level. You need to use optical quality glass or similar material that doesn’t block UV light.

How are your prints coming out?

Thanks for the responses. I’ll discuss them one at a time:

Linda asks: “Isn’t the problem with the PDMS that gets foggy – not the vat itself? It seems that you would still be replacing the pdms just as often.”

Yes, fogging is certainly one of the problems that the glass vat doesn’t solve. But the PDMS seems to adhere better to the glass, so the failure mode where the rubber peels off of the vat bottom due to a print sticking to it should be less common. And recoating should be easier, since one can remove the old PDMS layer without accidentally scratching the vat bottom.

Paul asks:

“Do you think the glass tray has a higher level of optical clarity compared to the plastic used by FormLabs?”

I do, although I have no way of quantifying that. I can say that it’s less likely to get fatally scratched or smudged, which can happen easily to the bottom surface of the plastic vat, and cleaning it is much easier.

Monger wrote:

"Using regular glass on the bottom is a bad idea. Glass blocks UV light on some level. You need to use optical quality glass or similar material that doesn’t block UV light.

How are your prints coming out?"

That’s a good point, and it’s the main reason why, after some research, I went with (expensive) borosilicate glass instead of cheap window glass, which is more fragile as well. I still wasn’t sure it would work, but I’ve done 3 prints so far and they all came out perfectly, which hadn’t been the case heretofore. The lack of “floaters” seems to have made a big difference - I noticed them in my tank recently after a single print made with a brand-new plastic vat and new resin. So far, after 3 prints with the glass vat, there are no globs of semi-cured resin cluttering up the tank and sticking to the prints. That’s something I wasn’t expecting, but I certainly don’t miss them.

Andrew Werby

www.computersculpture.com

1 Like

@Andrew_Werby So yes, please keep me informed about the fabricator. I would be interested in getting one.

-C

Sounds intriguing. Keep us posted, and add me to the list of those interested in getting one.

could these be shipped to the uk?!

Will do. Sure, the UK is within shipping range, but it would obviously cost more to ship it there. It would be good to get a few more people expressing interest here, so the fabricator can order enough glass and tool up for a small production run. I’d also like to hear from the Formlabs team, saying whether or not they have any objections to third parties selling tanks for their machines.

Andrew Werby

www.computersculpture.com

No, actually, it’s not a bad idea.

Pretty much any glass transmits 405nm just fine, including regular soda-lime glass.

In fact, i’ve used a tank made of plain ole soda-lime glass just fine on a different machine.

2 Likes

Good to hear. I assume that the thinner “tipping point” in the rear left of the tank will not be machined in? I always find that this cracks when removing the covers. Do the plastic covers from the plastic tanks fit the glass ones?

Thanks for the support, David! No we didn’t bother with the pouring spout, at least for the prototype. The plastic cover sort of perches on top, but doesn’t fit tightly, since the glass is thicker than the plastic was. I don’t think that matters much, though, since the glass on the edges isn’t orange, so light would get in that way even if it didn’t come in the top.

It’s interesting to hear that regular soda-lime glass would work, since it’s a lot cheaper. It’s also a lot more fragile, though, and if these have to get shipped, the trade-off may not be worth it. It would certainly be bad if the thing failed catastrophically while in place, since the resin would flow onto the inner works of the machine, which would be a real mess.

Andrew Werby

www.computersculpture.com

I’m game to buy a couple (if they’re coated and ready to go)!

Sure; this is the only picture I’ve taken of it so far. The trouble with Plexiglas (aka acrylic, the same thing the regular tanks are made from) is that it degrades if washed with isopropyl alcohol, so you can’t clean out the resin, and it’s nearly impossible to clean the window if you get a fingerprint or any gunk on it. So it seemed that glass was a better choice. It also adheres better to the silicone coating, so it doesn’t have that annoying tendency to peel away.

Sure; this is the only picture I’ve taken of it so far. The trouble with Plexiglas (aka acrylic, the same thing the regular tanks are made from) is that it degrades if washed with isopropyl alcohol, so you can’t clean out the resin, and it’s nearly impossible to clean the window if you get a fingerprint or any gunk on it. So it seemed that glass was a better choice. It also adheres better to the silicone coating, so it doesn’t have that annoying tendency to peel away.