I thought I’d share some thoughts on Form2. I’m running a design and prototyping workshop where with the team we work on wargames and boardgames miniatures, jewelry, trophies and props.

I bought Form2 to complement our Envisiontec machine. Especially to expand our ability to do larger projects while maintaining good quality.

First of all kudos to the sales team – while there where some initial hoops on my side of things they were super helpful, patient and professional (cheers Lucas!). They had no problems with processing our EU VAT ID, sent us pro-forma invoice quickly – it was a really hassle free process.

As soon as Formlabs registered our bank transfer it has taken around a week since the packages started arriving at our doors (I’ve ordered extra tanks and materials).

The assembly and software install was super simple. We’ve been able to get the machine running in a matter of minutes. It is really one of the few machines that you can start printing with so quickly after unboxing.

I love the improvements Formlabs team did on this machine. While I’ve been a fan for a long time (heck, I even flew to the 3D printing event in London when Form1 was presented), but there were some small shortcoming that impacted reliability on the previous printers - which simply made those not a very good fit for my needs.

I’m happy to say those nitpicks are gone. I had high hopes when I read about heated tank, enclosed optics, wiper – I thought those should alleviate most of the problems. And they did ![]() . So far I haven’t had a single failed print. We had one small damaged part – but it was basically my fault, I’ve been checking how much I can push the machine in terms of the way models are arranged and thus I’ve put it in a way I really shouldn’t. So I’m rather surprised it has printed at all . With sane arrangement it has been so far flawless.

. So far I haven’t had a single failed print. We had one small damaged part – but it was basically my fault, I’ve been checking how much I can push the machine in terms of the way models are arranged and thus I’ve put it in a way I really shouldn’t. So I’m rather surprised it has printed at all . With sane arrangement it has been so far flawless.

Apart from reliability the quality of the print and surface finish is something I enjoy. IMO it easily beats Projet / Objet machines and is getting closer to Envisiontec or DWS (J line). Mind - not there (would be jawdropping if it was), but for huge chunk of the projects it is really good enough.

Oh, and if you’ve encoutered complaints about spot size and you fear the quality might be not in your comfort territory – think about it like this: if you’re a skilled modelmaker / sculptor how often do work with tools that are 0.15mm thin? Not often, if at all, do you? And you still can get great result with those. The same applies to Form2 – you can achieve awesome results with it.

A huge part of whether a 3d printer is good or not hinges on how well hardware goes with software and materials available, not on a single spec. So it is rather sum of all parts. And in this respect Formlabs did their lesson.

As I’ve already praised hardware side I’ll move to software. I used apps for printers from Stratasys, DWS, B9, 3D Systems, Envisiontec and none of those is so welcoming and easy for a new user. It features exactly the number of features that are needed to prepare a build job – and it does it in welcoming and visually pleasing matter. I’m also surprised how well one click wizard works – I think for quite a lot of users it will be enough to get started.

I was a bit worried automatic support might not do the trick – but it does! Even though there are cases when you need to add support manually it takes seconds to do – simply choose adjust supports and click overhang area.

Lastly comes the resins – Formlabs offers quite extensive range of those. I look forward to testing some of the more fancy ones like tough or high temp. one . Those 2 I’ve aready used (grey and transparent) didn’t caused any problems – really shows the work to prepare settings for those. Oh, and kudos for small, but so handy feature – resin cartridge with auto fill. Really makes working with a printer a much cleaner process.

So as you might have already guessed with this glowing review I highly recommend Form2. So far I’m super happy with the purchase – it covered exactly the needs we had and it did it with style.

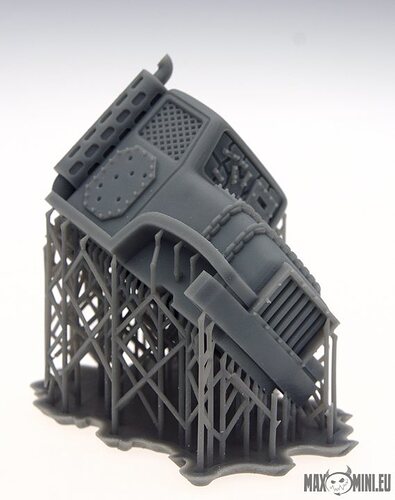

To put that in context – here are some of the first prints we did on it:

Is there something I wish for it to have in the future? Sure. But those are really minor enhancements I’d like to see – the machine is excellent as is.

What would those feature be? First of all I’d love to see a super matte resin. At this point I think only Envisiontec does such totally opaque resins (RCP30 for example). Those really make the prints look better and it is also easier to evaluate the printjob – especially on small, detailed parts.

Secondly I’d love to see some extra features in PreForm. For example I’d love to be able to get auto support feature without raising the model (so it sits on build plate). I have some edge cases where it would be beneficial. Also some numeric transforms (especially rotations). Unless I’m missing something those are tricky atm.

Lastly it would be awesome to get a Linux client, possibly packaged as an Appimage (so it would be distro-agnostic). For quite a bit of tasks I do it is better work platform – thus we have a couple of workstations that are Linux only. Ability to prepare printjobs without switching to OSX / Windows PC would come a long way. At this point we’ve come around this by setting up a virtual, Windows – based desktop.

edit: I’d also add longer lasting coating of the build tank. While it lasts longer now (I guess some of that thx to wiper) I think different type of coating would be even better (and that’s where I see biggest field of improvements to be made in SLA in general).